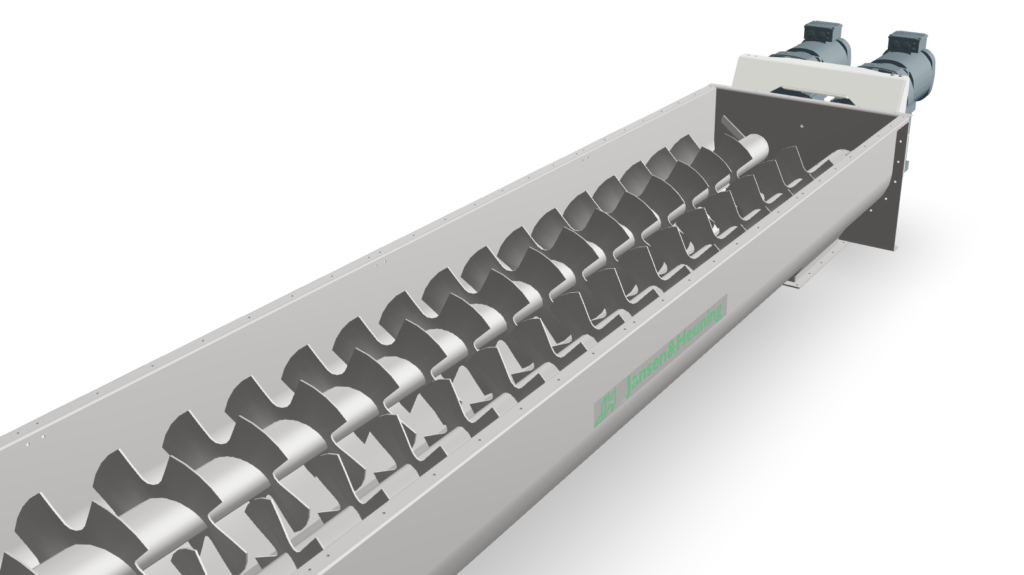

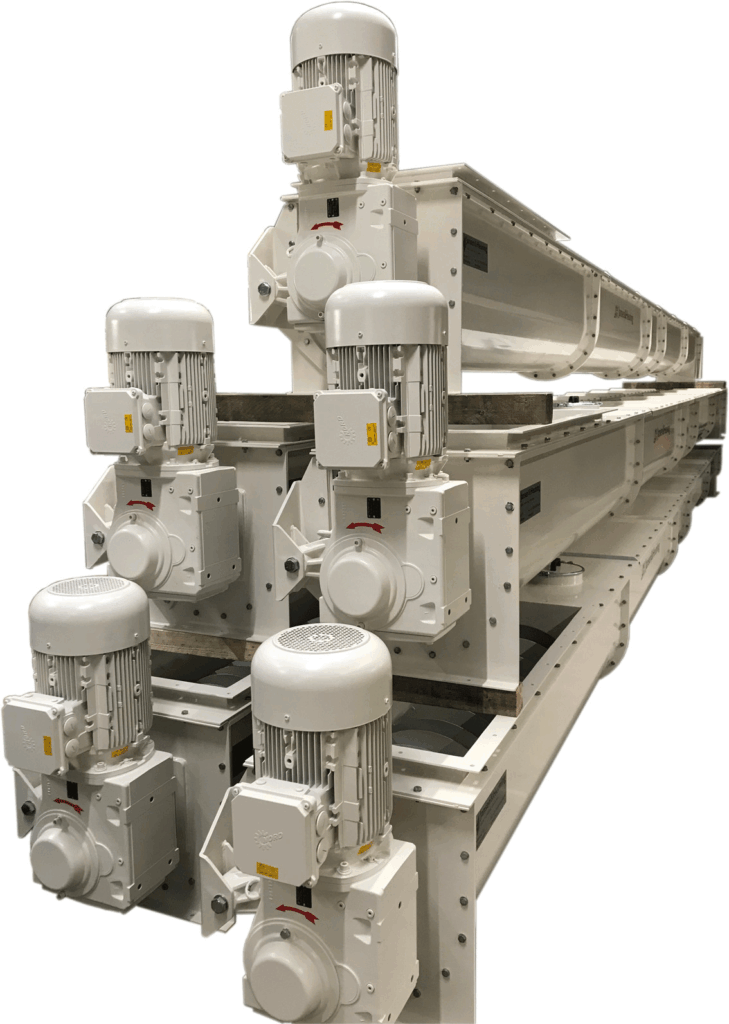

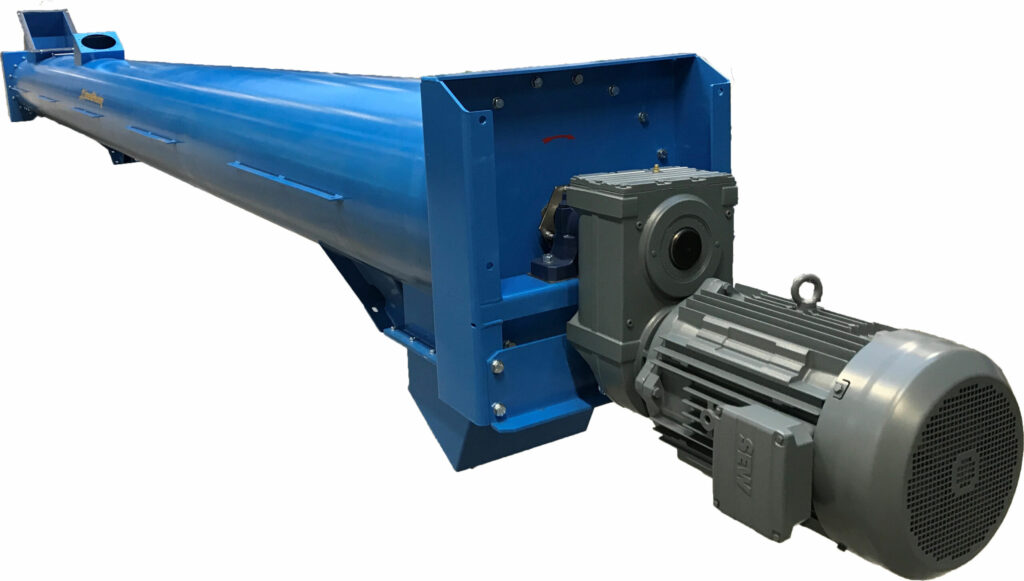

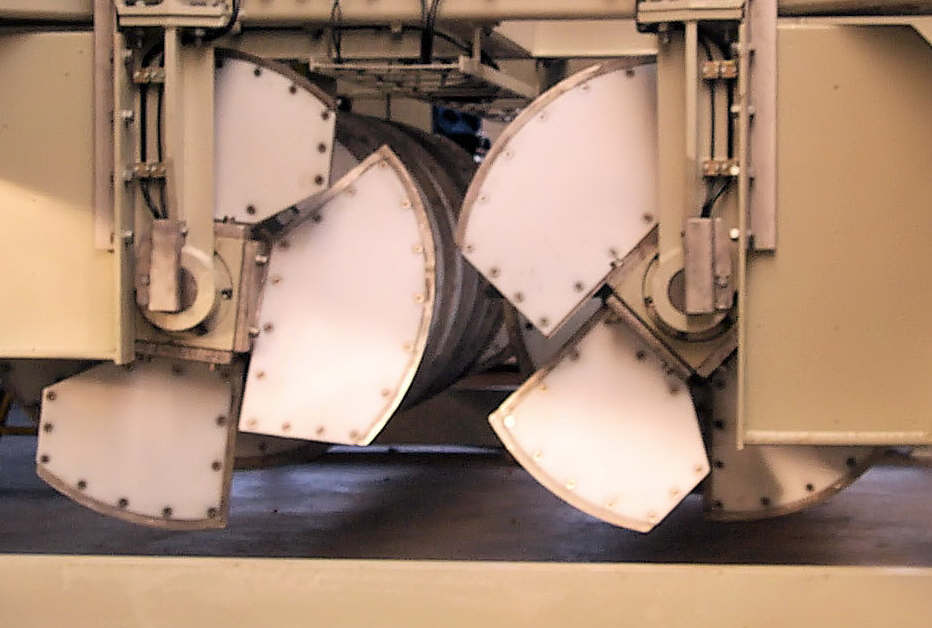

Jansen&Heuning produces screw conveyors for many products like flour, grain, salt, fertilizer, protein, waste products etc. For special applications like sticky products, shaft-less blade screws are used. Available as a U-trough or pipe screw for horizontal, sloping or vertical transport.

Screw-flights

- in St. 37, manganese steel, stainless steel, etc

- with central shaft or shaft-less

- pipe diameter depending on length and bending limits of the screw pipe

Bearing

- intermediate bearing required for longer screw conveyors, several possibilities:

– self adjusting ball bearings and lubricant return conduit

– split ball bearing bronze slide bearing

– cast iron slide bearing - external end bearing with stuffing box seals

- end shafts welded or with flange connection

Options

-

- paint system at customer’s choice or hot dip galvanization

- trough in Steel 37, stainless steel, manganese steel etc.

- covers secured with fasteners or bolts

- available systems: RPM monitoring, overflow prevention etc.

The JH calculation program enables you to calculate the costs of a conveying system for your specific situation. Fill in the required fields with your own data and the program will calculate the costs of the conveying system that best suits your needs.

The table shows our standard program. The drawings in production can be given within a few hours which, of course, works on the price. Do you want what we have not done before: no problem. We will work out with you.

| Specifications |

JHS 200

|

JHS 300

|

JHS 400

|

JHS 500

|

JHS 600

|

JHS 800

|

| screw blade diameter |

200

|

300

|

400

|

500

|

600

|

800

|

| drive shaft diameter |

40

|

50

|

60

|

70

|

80

|

100

|

| trough width excl. flange |

220

|

320

|

420

|

520

|

620

|

820

|

| trough width incl. flange/cover |

340

|

440

|

540

|

640

|

740

|

940

|

| height trough |

330

|

430

|

530

|

630

|

730

|

930

|

| capacity (m³/hr at 45% filling and v=0,6 m/s) |

20

|

54

|

100

|

170

|

217

|

430

|

| approximate dimensions, in mm | ||||||