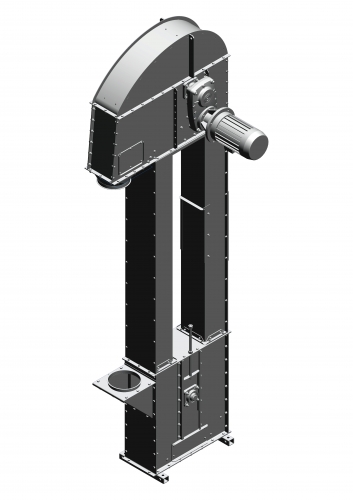

Description Chain conveyor grain

Jansen&Heuning’s grain chain conveyor is designed for efficient and dust-free conveying of grain and other granular bulk materials. With its fully enclosed housing and modular construction, this conveyor offers optimum performance with minimal maintenance. The conveyor stands out for its robust design, flexibility and reliability, and is widely used in grain processing plants and industrial facilities.

Chain conveyor suitable for

The fully enclosed chain conveyor is ideal for situations where dust formation must be kept to a minimum. This type of conveyor is excellent for horizontal or slightly inclined transport of grain and similar bulk materials. Thanks to its modular design, the chain conveyor can easily be adapted to any specific application, such as grain storage sites, silos, landfills and processing plants. Feel free to also compare with our bucket elevator and screw conveyors for alternative transport solutions.

Chain conveyor equipped with

- Fully enclosed housing to reduce dust emission

- Modular construction in 25 cm length steps

- Pulley and chain tensioning section with powerful geared motor

- Self-cleaning reversing section for minimum maintenance

- Several intermediate outlets possible, both manually and electrically operated

- Transport in both directions for optimum flexibility

- Side inlet suitable for use in storm drains

- Durable plastic bottom reduces wear

Advantages of chain conveyor grain

The chain conveyor offers several advantages over alternative conveying systems. Its closed design minimises dust formation, making the working environment cleaner and safer. Its low-maintenance and modular design makes this system easy to adapt to changing needs or future expansions. Its energy-efficient and quiet operation make this conveyor highly suitable for continuous operation, contributing to lower operating costs.

Chain conveyor types

Various options are available for the chain conveyor, including silo support material, collapse boxes, extended carriers and capacity controllers.

| 25 – 60 t/h | 60 – 120 t/h | ||||||

| Type | SR25 | SR40 | SRL60 | SR60 | SR80 | SR100 | SR120 |

| Capacity in t/h* at 0.5m/s | 25 | 40 | 60 | 60 | 80 | 100 | 120 |

| Plate thicknesses bottom/side/top | 3/2/1,5 | 3/2/1,5 | 3/2/1,5 | 3/3/2 | 3/3/2 | 3/3/2 | 3/3/2 |

| Plastic carriers | v | v | v | ||||

| Plastic bottom 10 mm | v | v | v | v | |||

| V-belt drive | v | v | |||||

| Geared motor | v | v | v | v | v | v | v |

| Weight full/empty (kg) | 24/36 | 30/61 | 34/76 | 52/102 | 57/119 | ||

| Chain | 38.4R | 38.4R | 38.4R | FV125 | |||

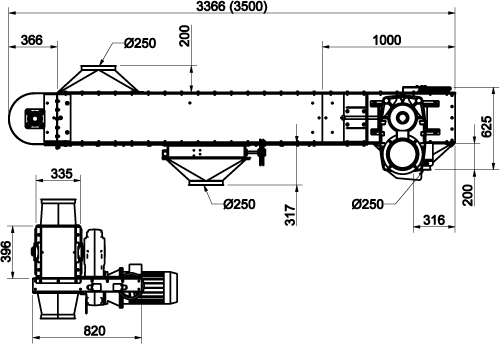

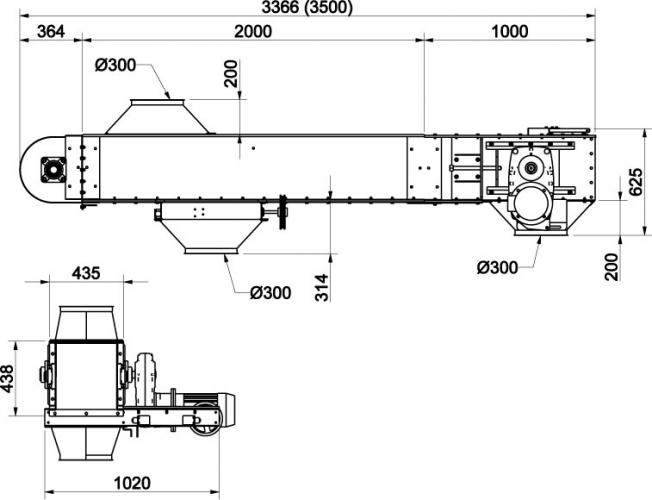

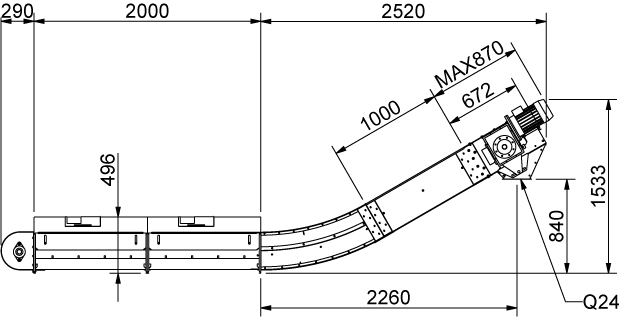

| Inlet/ Outlet | Q16/Ø150 | Q20/Ø200 | Q24/Ø250 | Q24/Ø250 | Q30/Ø300 | ||

*At0,7 kg/m³

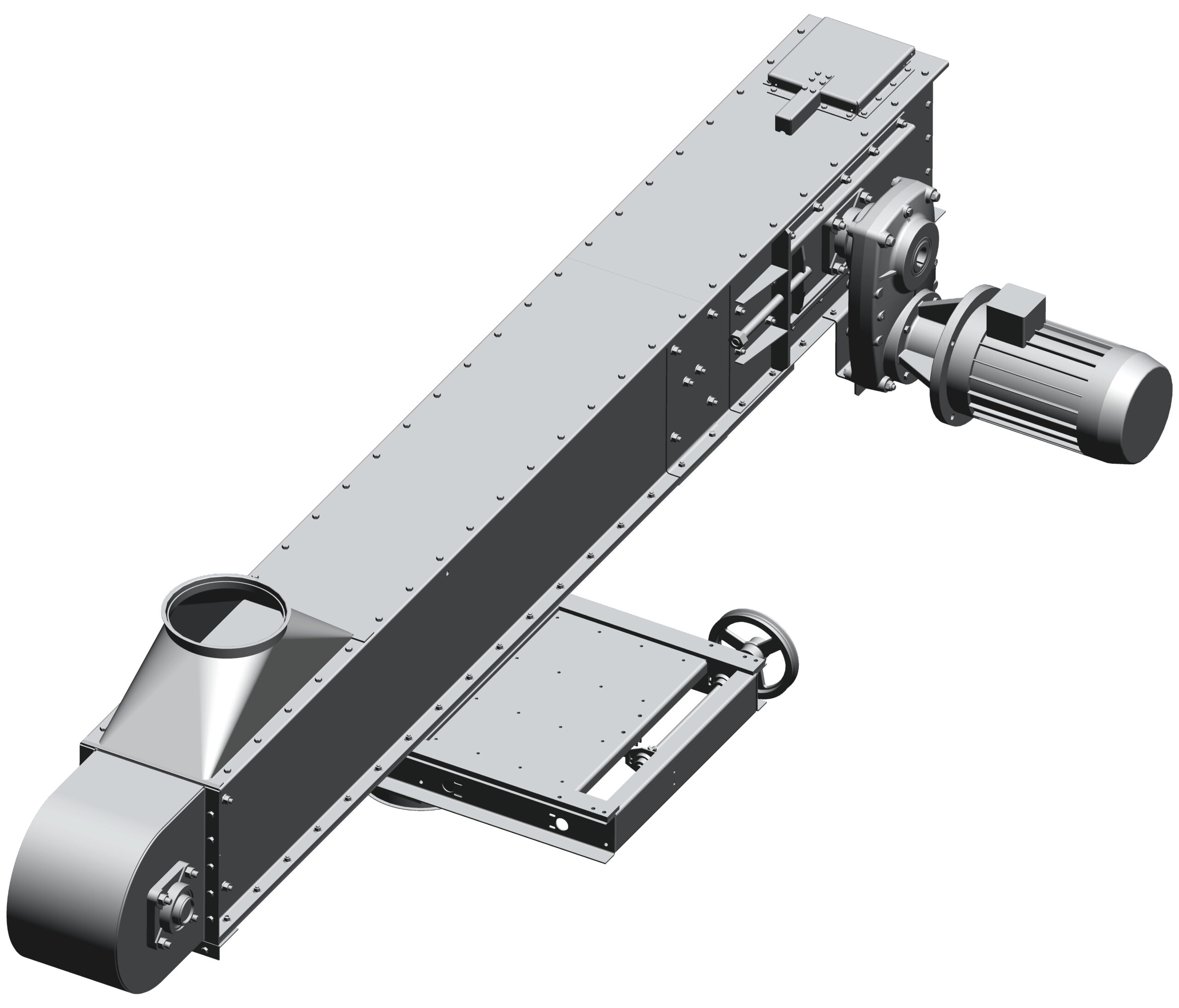

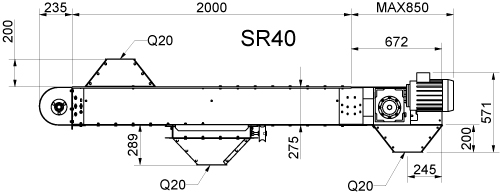

SR40

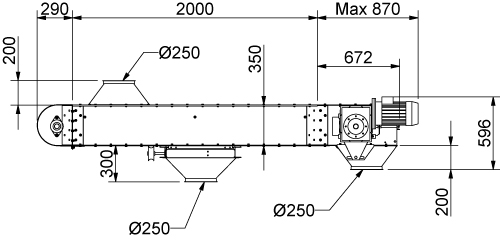

SRL60

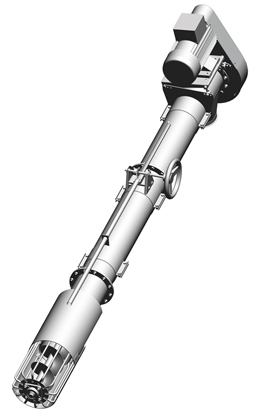

SR60-SR80

SR100-SR120

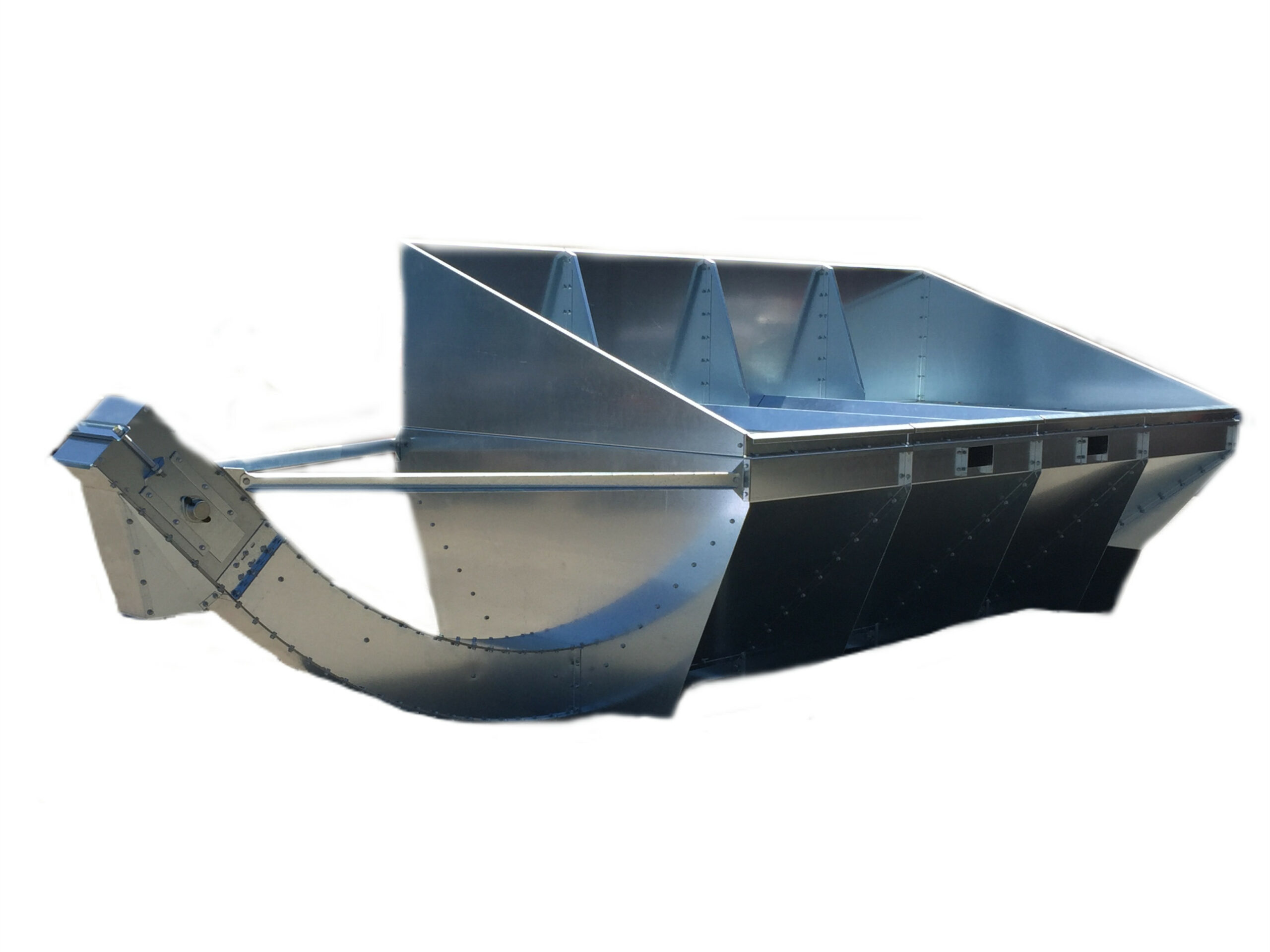

SRL60 + bocht (ook mogelijk bij andere types)

Options for chain conveyor grain

- Extended carriers for specific product characteristics

- Infeed bins and side inlets

- Extra capacity control for precise dosing

- Integrated spot filters for additional dust reduction

Contact

For more information or a tailored quotation, please contact Jansen&Heuning:

- Phone: +31(0)50 3126 448

- Email: sales@jh.nl

- Contact form: https://www.jh.nl/en/contact/