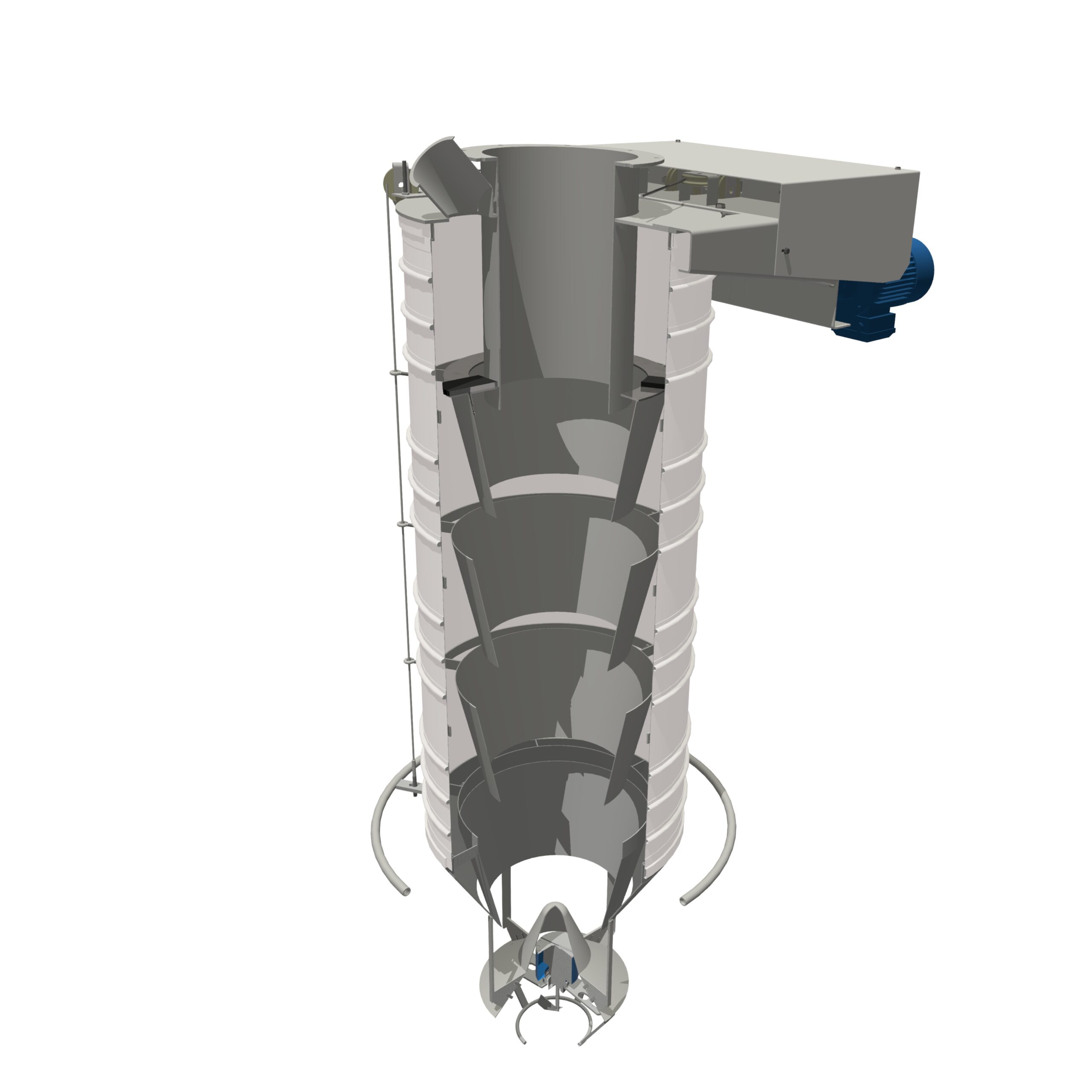

Description Loading bellows JHBB300

The loading bellows JHBB300 was developed for dust-free loading of powders and granulates into bulk trucks, ships, and storage halls. A separate product channel and integrated dust extraction system reduce dust emissions effectively during the loading process. With minimal mechanical components and the use of durable materials, the JHBB300 offers a long, low-maintenance service life. The outer cover is made of reinforced PVC, and lifting is achieved via three externally mounted stainless steel cables. The loading bellows JHBB300 is part of a modular range of high-quality loading bellows engineered and assembled by Jansen&Heuning.

Suitable for

The loading bellows JHBB300 is used for the controlled loading of fine bulk materials such as powders, flour, and granulates. It is suitable for filling both closed and open bulk trucks, as well as ship loading and indoor storage. Due to its compact build and dust-tight operation, this model is ideal for use in the food industry, chemical sector, and building materials logistics. Its effective dust control system ensures compliance with modern workplace safety and environmental standards.

Standard sizes

| Modules | without closing cone | with closing cone | ||||

| retracted | difference | extended | retracted | difference | extended | |

| 1 | 415 | 600 | 1015 | 785 | 320 | 1105 |

| 2 | 460 | 900 | 1360 | 830 | 620 | 1450 |

| 3 | 505 | 1200 | 1705 | 875 | 920 | 1795 |

| 4 | 550 | 1500 | 2050 | 920 | 1220 | 2140 |

| 5 | 595 | 1800 | 2395 | 965 | 1520 | 2485 |

| 6 | 640 | 2100 | 2740 | 1010 | 1820 | 2830 |

| 7 | 685 | 2400 | 3085 | 1055 | 2120 | 3175 |

| 8 | 730 | 2700 | 3430 | 1100 | 2420 | 3520 |

| 9 | 775 | 3000 | 3775 | 1145 | 2720 | 3865 |

| 10 | 820 | 3300 | 4120 | 1190 | 3020 | 4210 |

| 11 | 865 | 3600 | 4465 | 1235 | 3320 | 4555 |

| 12 | 910 | 3900 | 4810 | 1280 | 3620 | 4900 |

| all dimensions in mm | ||||||

Designed with

- Internal inlet diameter Ø 300 mm with flange connection

- Separate product and dust channels with automatic closure in retracted position

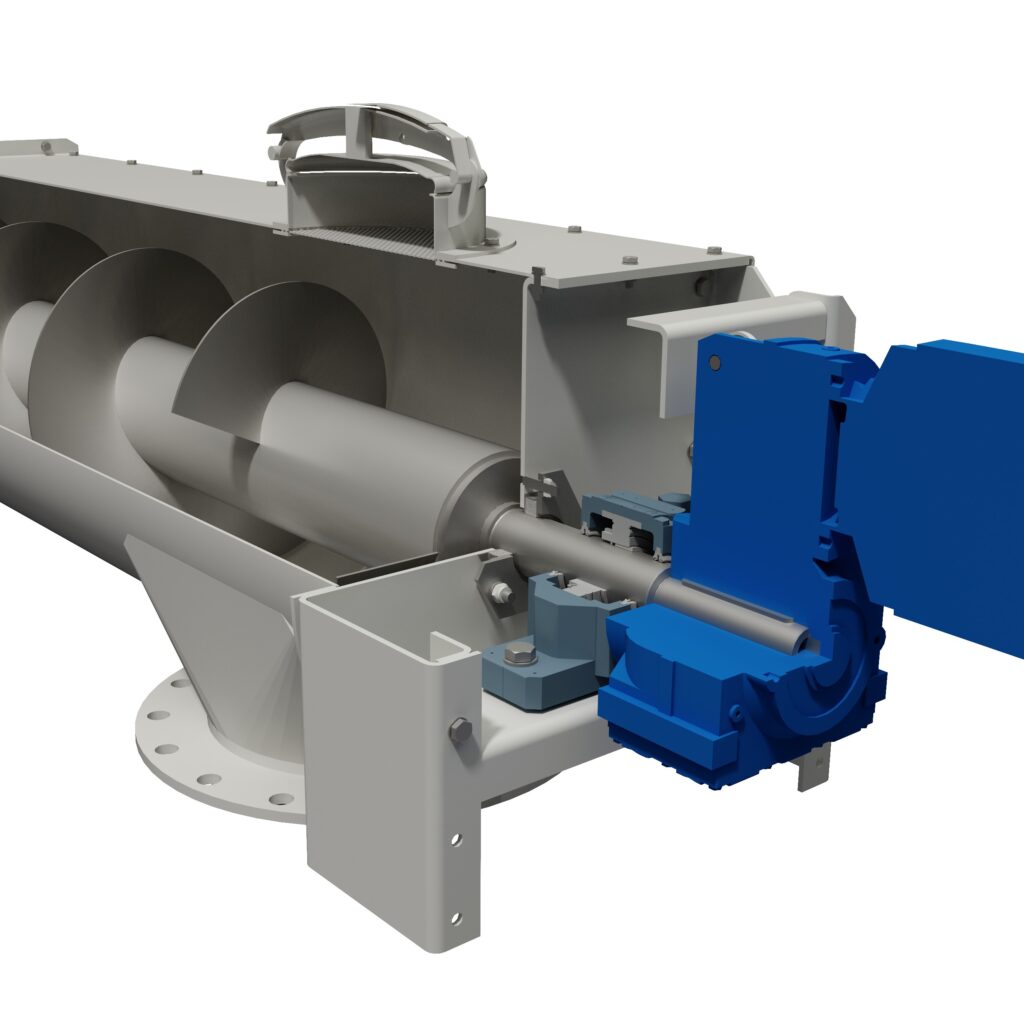

- Pulley system with 0.55 kW motor (up to 12 modules)

- Stainless steel lifting cables and plastic sheaves

- Outer cover made of 500 g/m² fibre-reinforced PVC

- Nestable product guides and flexible outer sleeve

- Rope tension monitoring (slack and taut detection)

- Contact parts in steel 37 or stainless steel 304

- Configurable lengths from 1 to 12 meters

- Standard outlet with loading cone or dust skirt

Advantages of

This loading bellows provides efficient and dust-free loading with minimal product spillage. Its compact vertical lift mechanism allows for easy integration into both new and existing bulk installations. The loading bellows JHBB300 ensures reliable operation with a low number of moving parts, which reduces wear and simplifies maintenance. The closed system protects personnel and the environment from airborne dust, making it a robust and compliant solution for industrial bulk handling.

Optional

- Double-walled outlet cone for enhanced dust extraction

- Rubber-coated outlet for improved sealing on truck inlets

- Closing cone to prevent residual dust fall

- Capacitive or rotating level sensor

- Control cabinet with auto-tracking system for bulk truck loading

- Automated fill tracking for open-top containers

- Manual push-button operation (pendant control)

- On-site installation by Jansen&Heuning technicians

- Full stainless steel version for corrosive environments

Contact

For more information or a tailored quotation, please contact Jansen&Heuning:

- Phone: +31(0)50 3126 448

- Email: sales@jh.nl

- Contact form: www.jh.nl/en/contact