Description Disc mill

Jansen&Heuning’s disc mill grinds dry bulk materials without the use of sieves. The machine is equipped with one fixed and one rotating disc. Via a spindle, the distance between these discs is infinitely adjustable, also during operation. As a result, the grain size of the final product can be adjusted quickly and accurately.

With no parts lying around, the disc mill produces considerably less noise than a hammermill. This quiet operation makes the machine suitable for locations where people work in the immediate vicinity. Compared to hammermills, the disc mill consumes about 10% less energy per tonne of product.

Disc mill suitable for

The disc mill is suitable for fine grinding dry raw materials such as grain, maize or feed components. It is often used in compound feed plants, pre-treatment lines or industrial milling lines where energy efficiency and noise reduction are important.

Equipped with

- Fixed and rotating disc

- Continuously adjustable disc spacing

- Low-noise enclosed housing with no parts lying around

- Wear-resistant grinding discs (service life up to 10,000 tonnes)

- Robust mechanical drive

Benefits of the disc mill

- No sieve required thanks to adjustable grinding distance

- Granule size adjustable during rotation

- Up to 10% lower energy consumption than hammer mills

- Capacity of 6 tonnes/hour (standard), up to 24 tonnes/hour on request

- Suitable for industrial environments with continuous operation

Capacity in tons/ hour

| Typ | SK2500 | SK5000 | |||

| kW | 7,5 | 15 | 22 | 30 | |

| Barley | 1-1,9 | 1,7-3,2 | 2,4-4,7 | 3-6 | |

| Wheat | 1-2 | 1,8-3,5 | 2,5-5 | 3,2-6,5 | |

| Maize | 0,7-2 | 2-3,5 | 2,5-5 | 3-6,5 | |

| Oats | 0,8-1,3 | 1,4-2,3 | 2-3,2 | 2,4-4,5 | |

| Peas | 0,75-2 | 2-3,5 | 2,5-5 | 3-6,5 | |

capacity in tons/hour when crops are dry and well cleaned

the capacity decreases by ca. 5% each time the moisture content increases by 1% (for example: 18% moisture content reduces the capacity by (18-15) x 5 = 15% )

Technical specifications

| SK2500 | SK5000 | |

| disc diameter (mm) | 300 | 450 |

| disc distance regulation | manual or automatic | manual or automatic |

| disc distance min./max. (mm) | 0-10 | 0-10 |

| inlet, round (mm) | Ø150 | Ø150 |

| outlet, rectangle (mm) | 300 x 87 | 482 x 101 |

| motor (rpm) | 3000 | 3000 |

| noise level (dB) | 80 | 80 |

| weight (kg) | 120 | 335 |

Dimensions

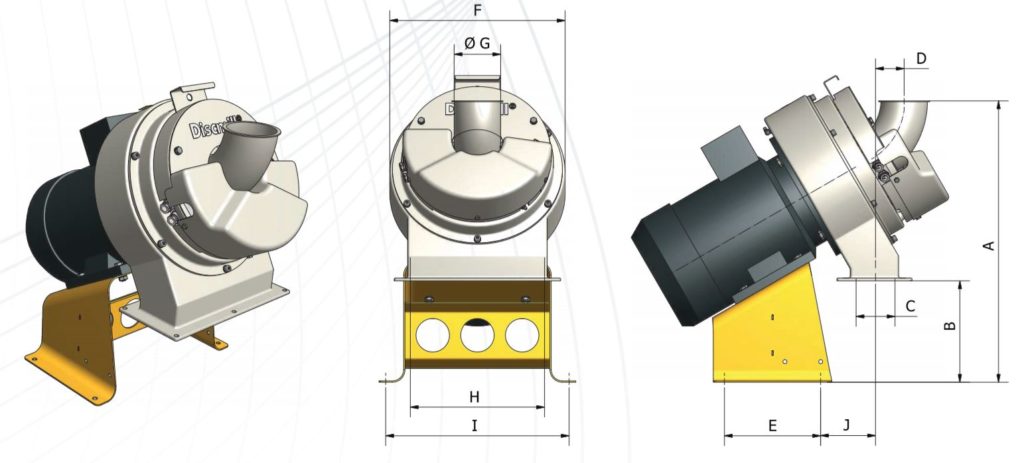

Disc mill with adjustable grinding gap. Image shows technical dimensions and inlet/outlet configuration.

Disc mill with adjustable disc spacing, suitable for 6 to 24 tonnes/hour. Picture shows dimensions and connection positions.

| SK2500 | A | B | C | D | E | F | G | H | I | J |

| 7,5 kW | 779 | 227 | 87 | 60,5 | 215 | 392 | 150 | 300 | 410 | 123 |

| SK5000 | A | B | C | D | E | F | G | H | I | J |

| 15 kW | 884 | 325 | 101 | 58 | 400 | 582 | 150 | 482 | 482 | 130 |

| 22 kW | 894 | 335 | 101 | 58 | 400 | 582 | 150 | 482 | 482 | 126 |

| 30 kW | 921 | 360 | 101 | 58 | 400 | 582 | 150 | 482 | 482 | 107 |

Optional

- inlet Ø150 mm with 3 or 4 inlets

- magnet on inlet

- outlet funnel

- extension of feet

Contact

For more information or a tailored quotation, please contact Jansen&Heuning:

- Phone: +31(0)50 3126 448

- Email: sales@jh.nl

- Contact form: www.jh.nl/en/contact