Description Sieve shaker grain

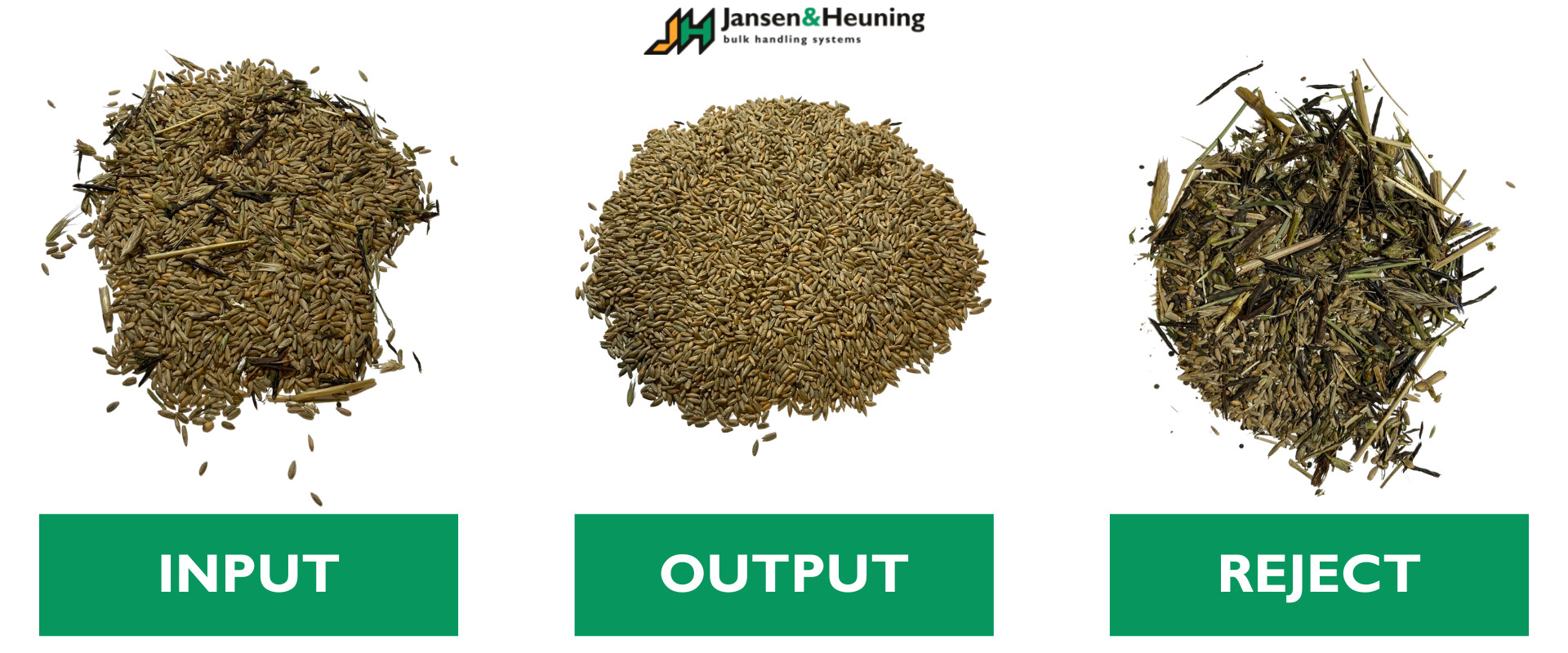

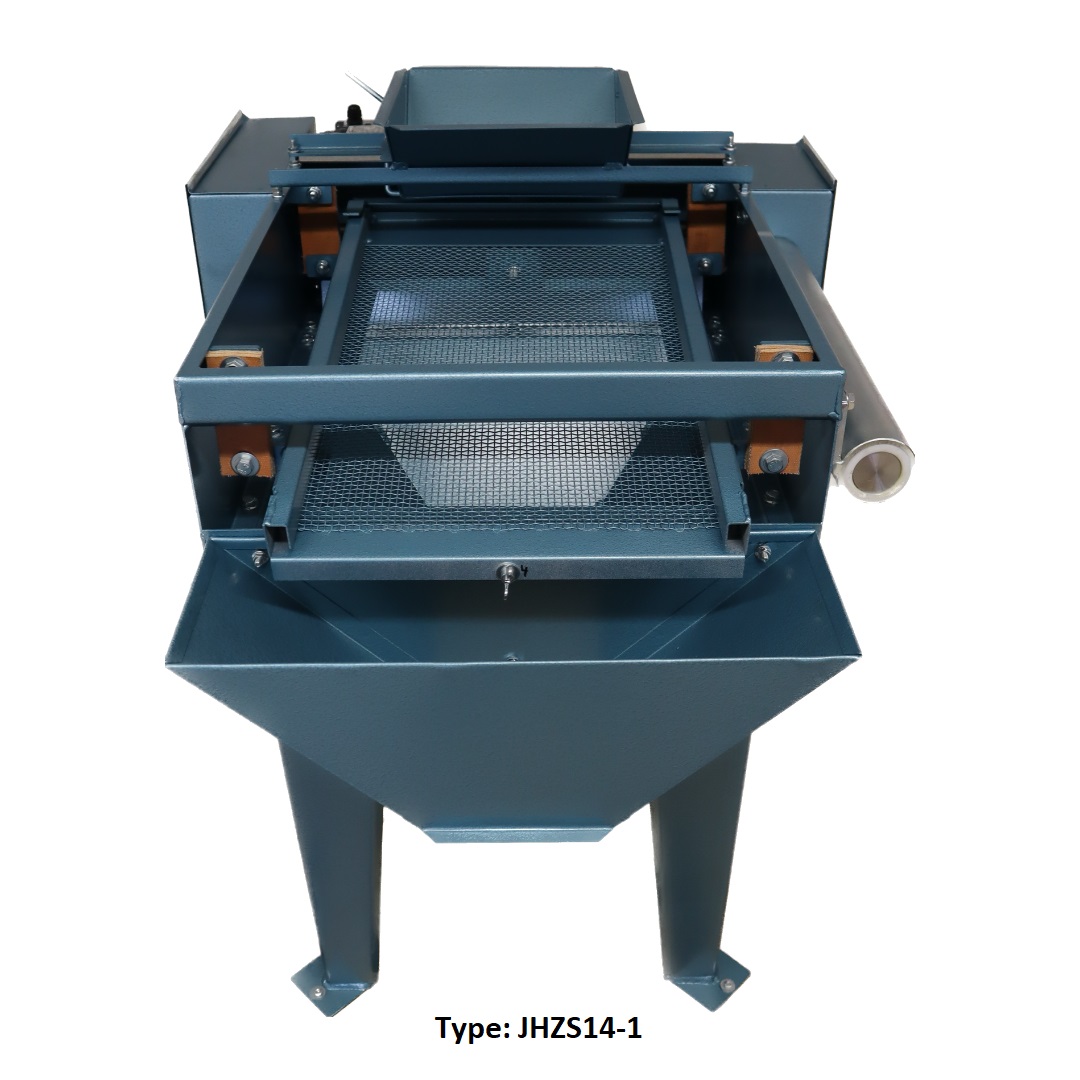

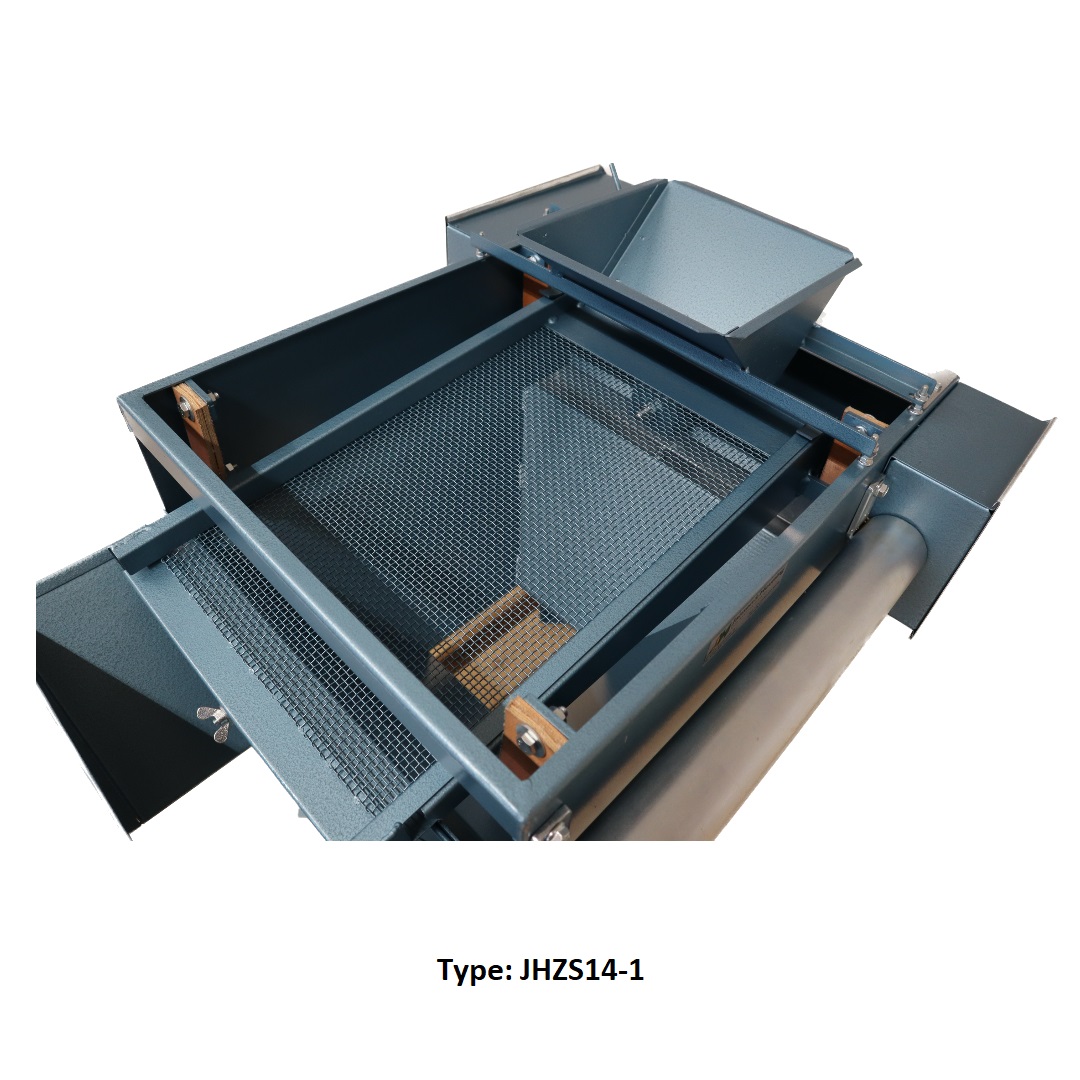

The sieve shaker: the easiest machine for separating large and/or fine particles from grain. A shaking mechanism sets the sieves in motion and the grain flows gently over the machine. By using both a bottom and top sieve, the coarse parts (straw, stones) and the fine parts (small grains, sand, weed seeds) can be separated from the main product.

These sieves are commonly used in feed lines at barns and before the product is milled. Cleaning grain also contributes to more efficient post-harvest drying, as the moist waste parts affect the drying process negatively.

| type | sieve size (dm²) | number of sieves | capacity (t/h) |

motor (kW) | dimensions (lxwxh) | weight (kg) |

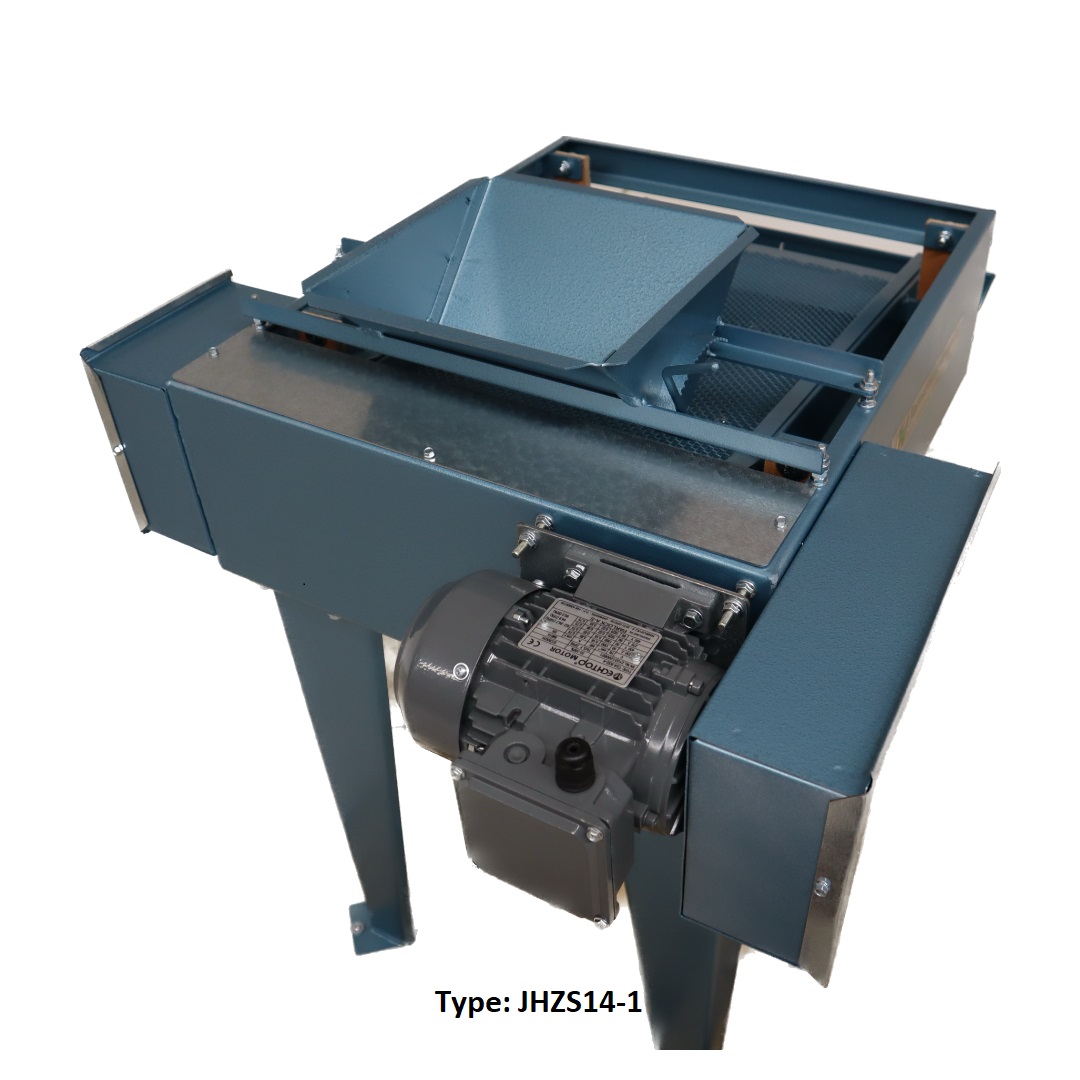

| JHZS14-1 | 14,4 | 1 | 2 to 4 | 0,18 | 970x660x800 | 70 |

| JHZS14-2 | 14,4 | 2 | 1 to 2 | 0,18 | 1000x550x950 | 77 |

| JHZS31-1 | 31 | 1 | 4 to 6 | 0,18 | 1220x830x800 | 94 |

| JHZS31-2 | 31 | 2 | 2 to 5 | 0,18 | 1200x700x1300 | 146 |

Sieve shaker results

Specifications sieve shaker for grain

- light engine (low power consumption)

- can be delivered legless

- sieves are easily changeable

- inlet with control slide

- compact

The JHZS14-2 and JHZS31-2 are standard delivered with an upper sieve Ø2,5 mm and bottom sieve #8,0 mm. The upper sieve is also deliverable in Ø2,0 – Ø3,0 – Ø4,0 – Ø5,0 – Ø6,0 mm. Bottom sieves are deliverable in the following sizes: #4 – #6 – #10 #12 mm (wire sieve).

The JHZS14-1, JHZS31-1 and JHZS41-1 are standard delivered with a sieve of #8,0 mm. Also available in #4 – #10 – #12 mm (wire sieve).

Options:

- different sizes of hoppers for processing larger batches

- extraction system for removing light straw/chaff and dust particles (see photo’s)