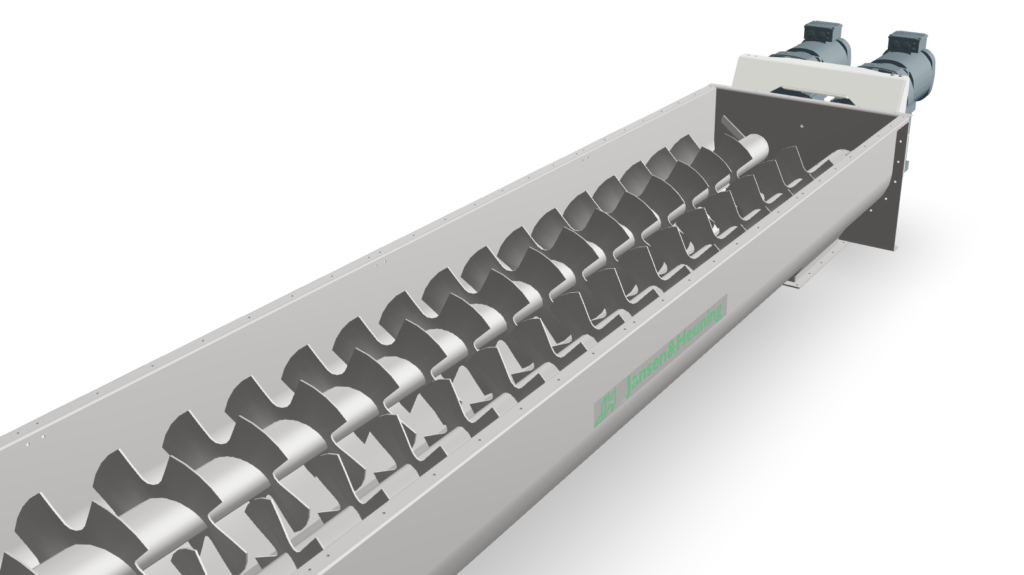

Description Paddle mixer

The JHMX10000 paddle mixer has been developed for intensive and uniform mixing of dry bulk goods. The installation has two counter-rotating shafts with adjustable paddles that ensure continuous mixing. With a net capacity of 10,000 dm³ and a processing capacity of 45 tonnes per hour, this mixer is suitable for heavy-duty industrial applications. Its robust construction and maintenance-friendly design make this paddle mixer ideal for continuous use in demanding production environments. The industrial mixer is one of the special bulk machines manufactured by Jansen&Heuning.

Suitable for

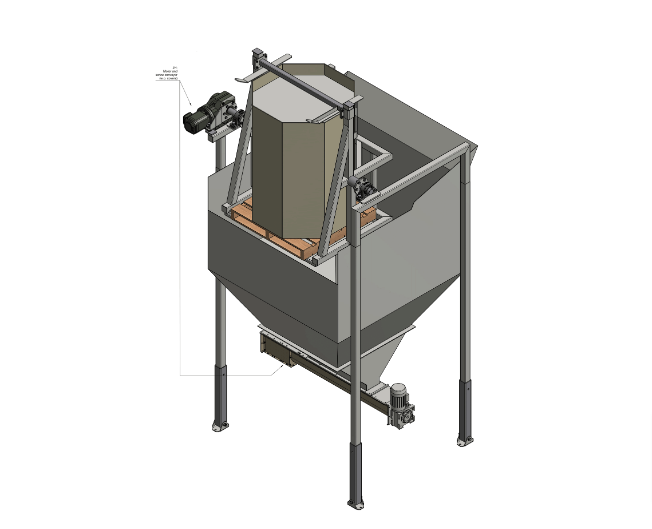

This industrial paddle mixer is suitable for mixing powders, granulates and slightly moist products. Common applications can be found in the chemical, mineral processing, feed, recycling and building materials industries. The installation performs optimally in processes where product homogeneity, short mixing times and limited mechanical product loading are required. A popular alternative is the continuous mixer.

Paddle mixer equipped with

- Double mixing shaft with counter-rotating paddles

- Power of 110 kW

- Net capacity of 10,000 dm³

- Capacity of 45 tonnes/hour

- Steel construction with integrated inspection hatches

- Safe and dust-proof shielding

- Connectable drive via gearbox

- Customised connections for inlet and outlet

Advantages of the paddle mixer

The paddle mixer offers an efficient solution for homogeneous mixing with low shear. The system combines high capacity with controlled product movement, resulting in uniform mixing without product degradation. Its modular design allows easy integration into existing installations. Maintenance is simplified thanks to generous inspection access and robust components with a long service life.

Technical design tailored to your process

Each paddle mixer is built to fit the installation in which it will be used. Dimensions, power and materials are defined based on the product, the process and the surrounding conditions.

Contact parts can be made from stainless steel, such as AISI 304 or AISI 316. For applications with explosion risk, an ATEX-compliant design is available. Lids can be lockable and equipped with safety sensors. Both thermal and acoustic insulation are possible.

For automatic discharge, pneumatic valves can be integrated. Vibration dampers ensure low-vibration installation. If required, a PLC control system can be included, with recipe management and data logging.

Contact

For more information or a tailored quotation, please contact Jansen&Heuning:

- Phone: +31(0)50 3126 448

- Email: sales@jh.nl

- Contact form: www.jh.nl/en/contact