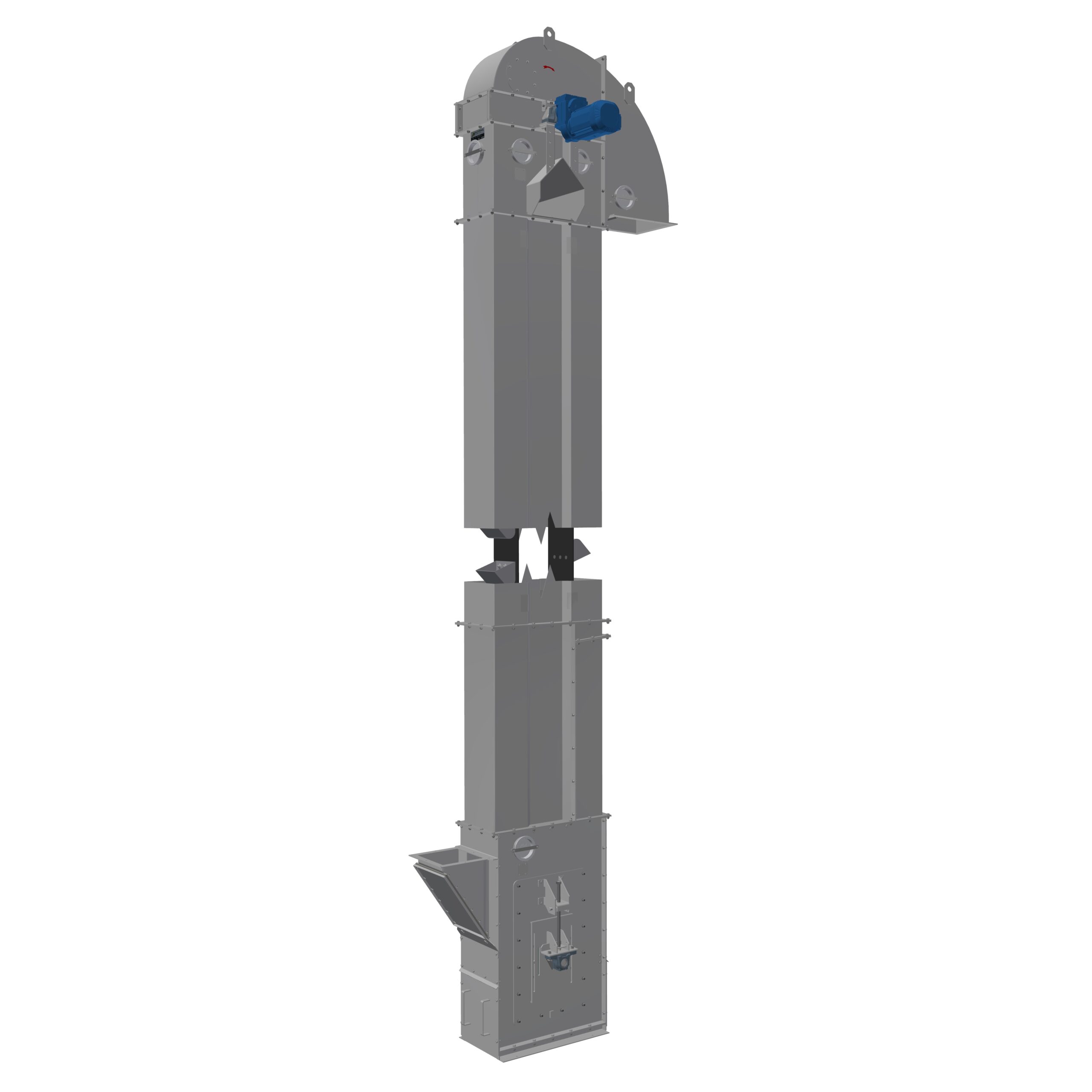

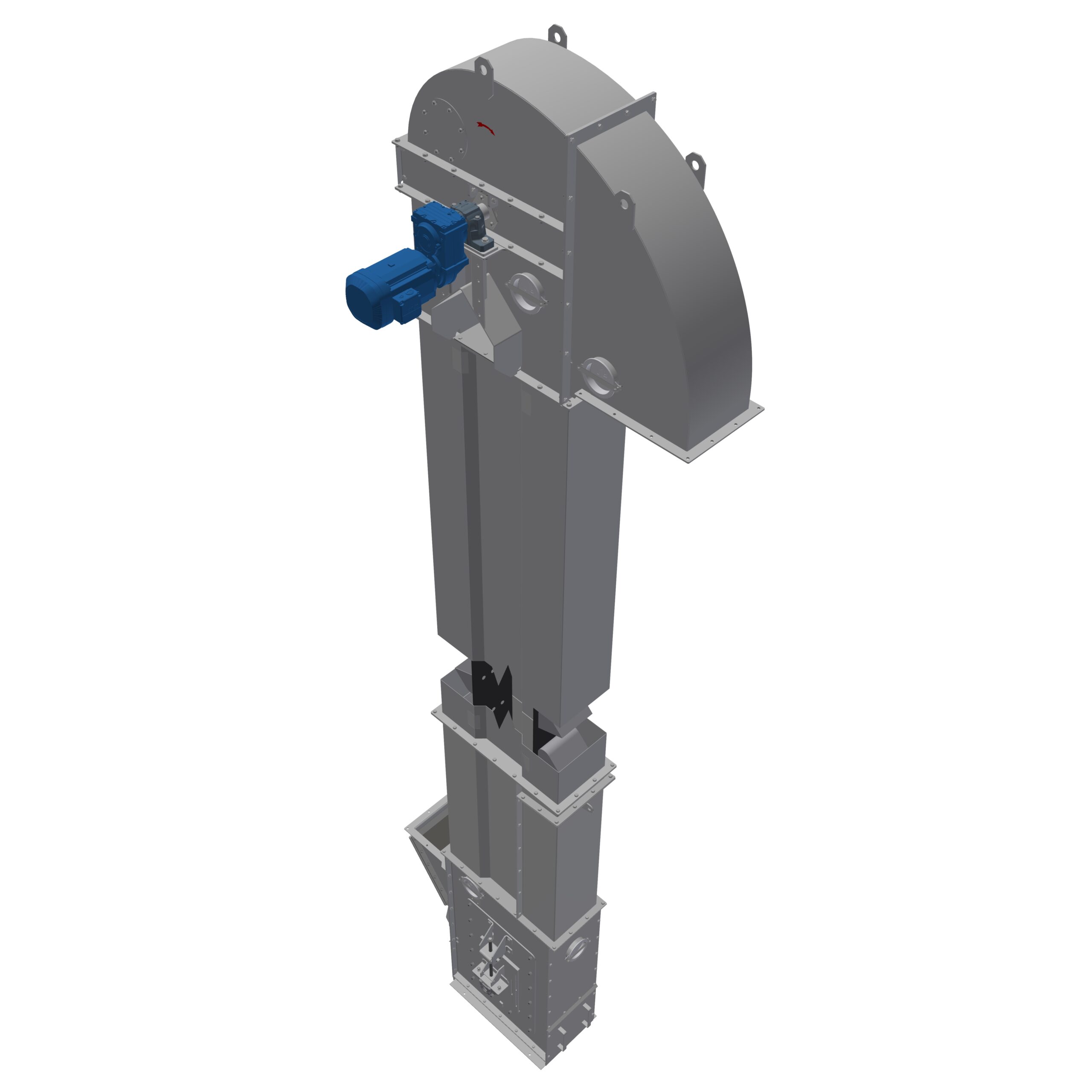

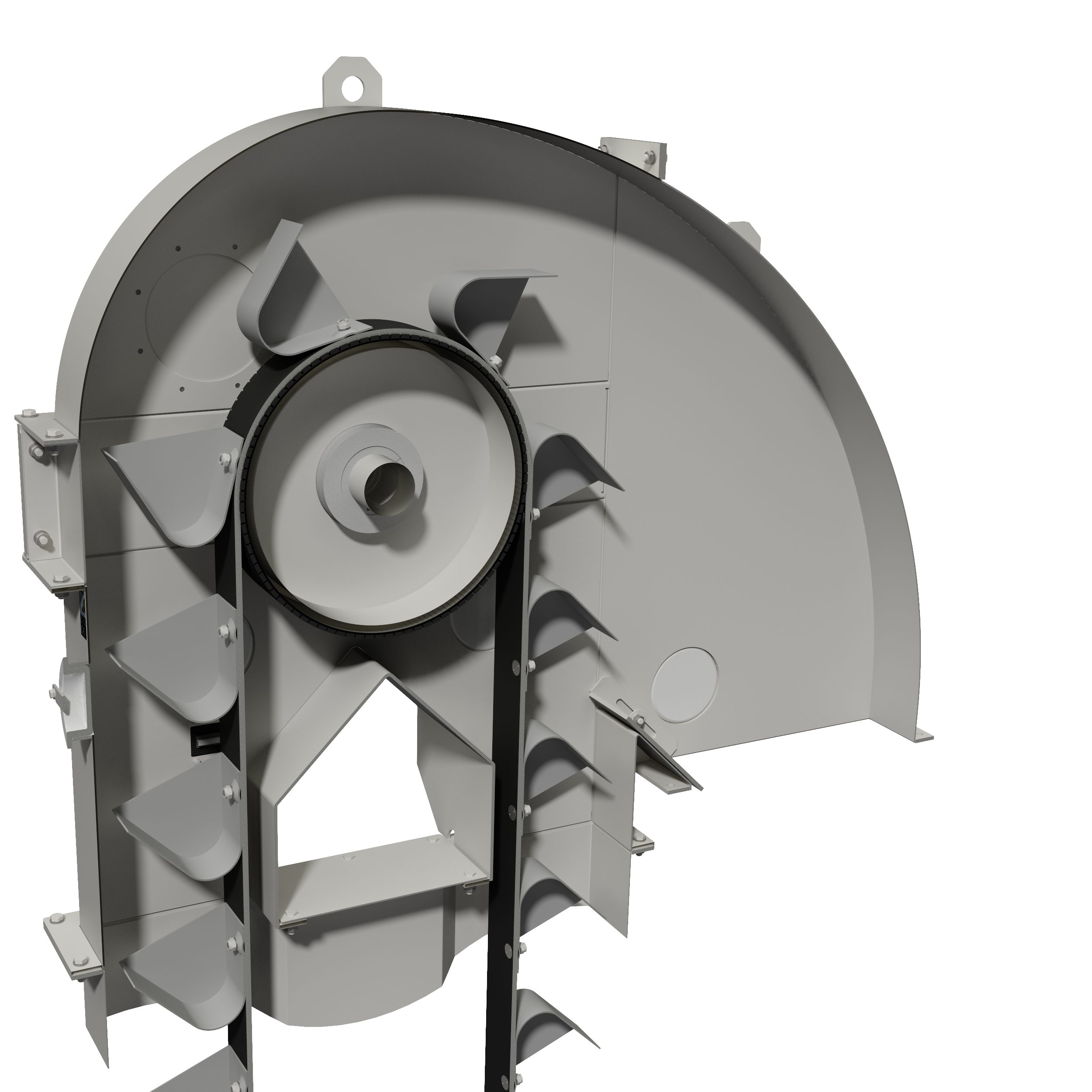

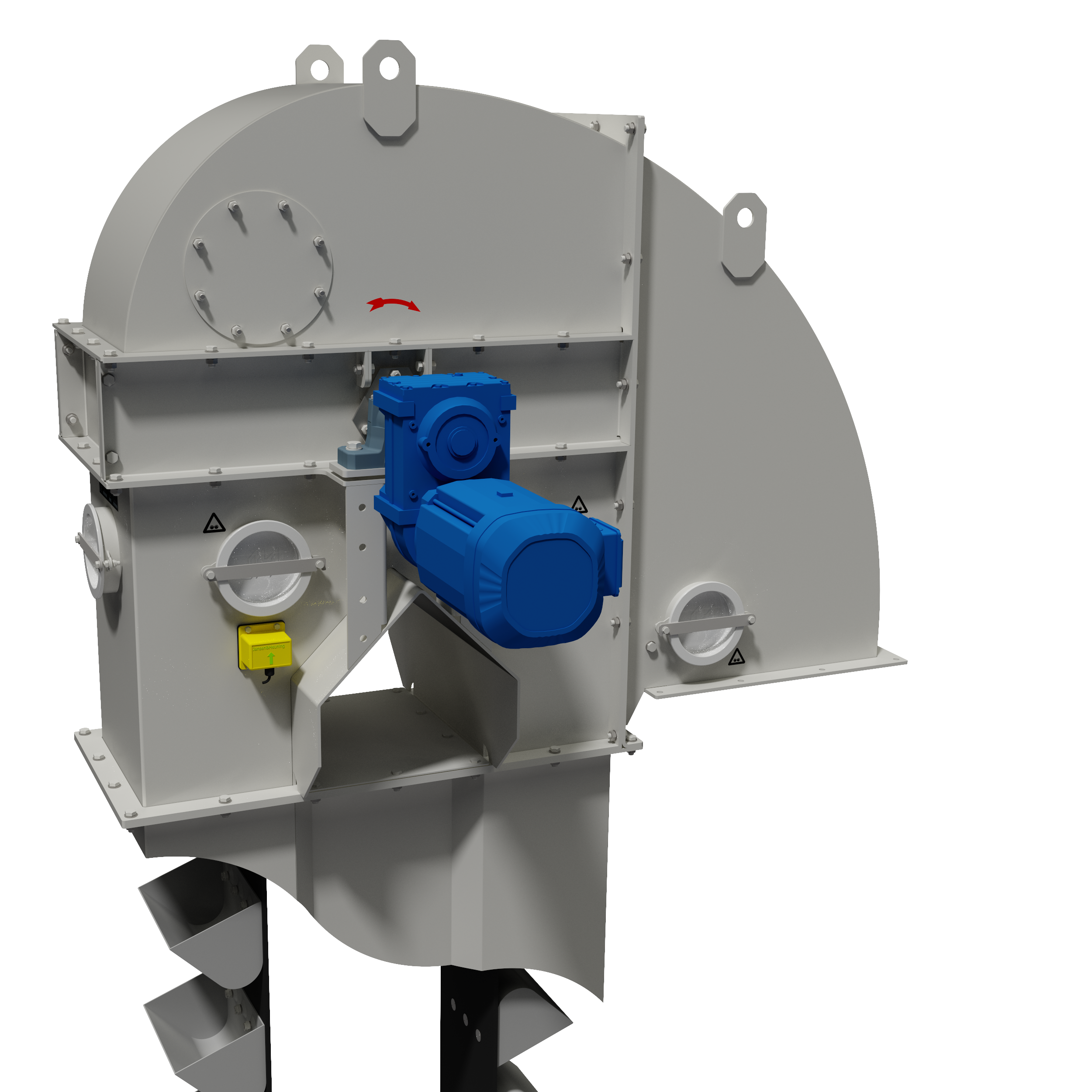

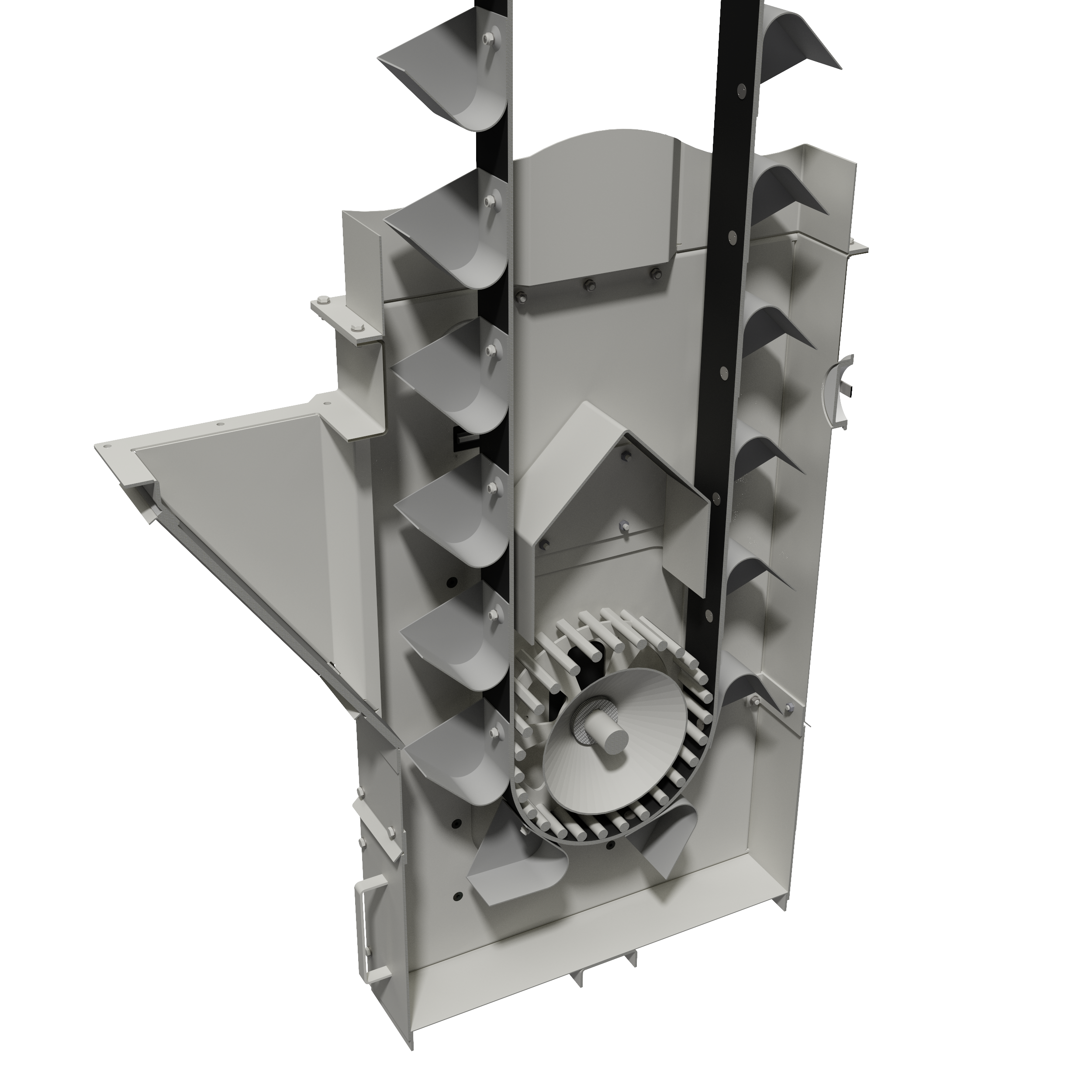

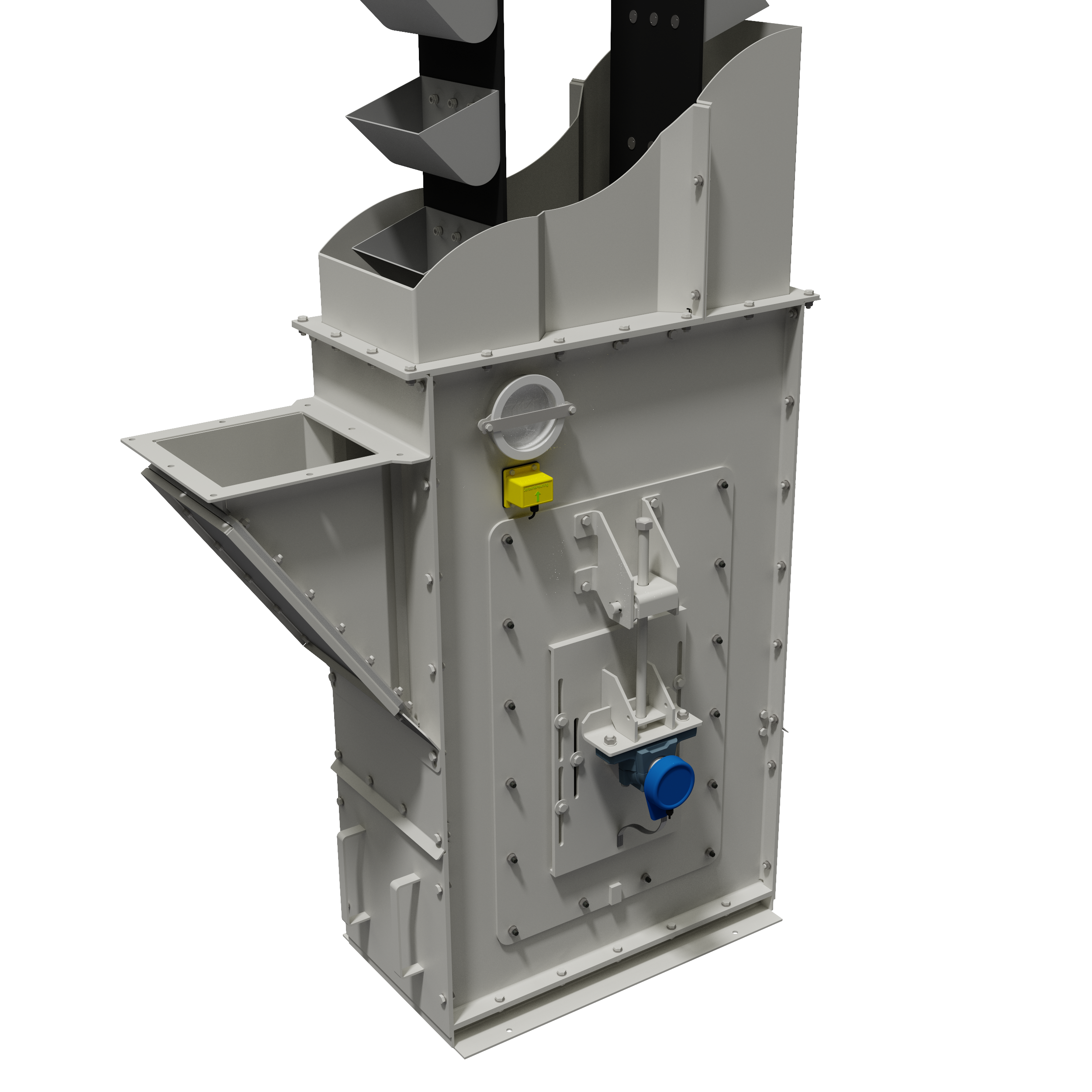

Description Bucket elevator

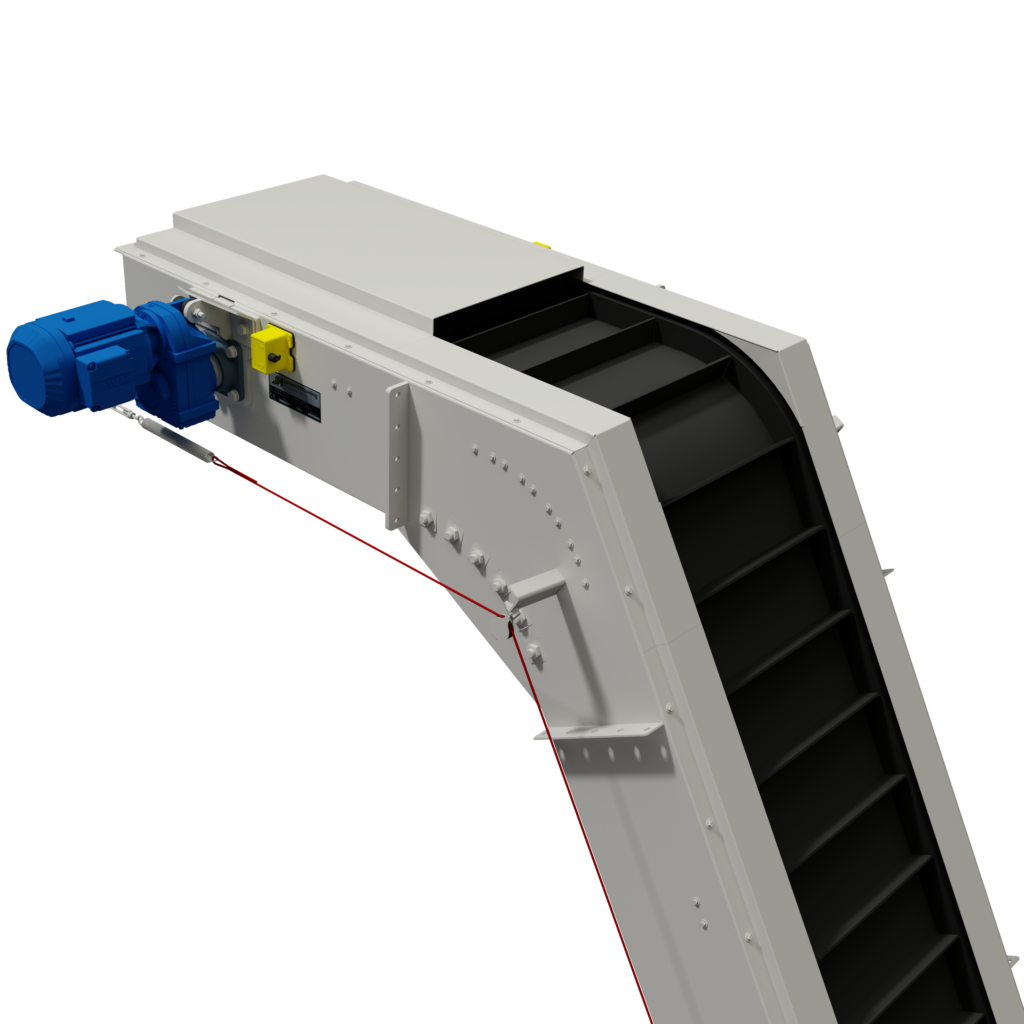

The bucket elevator by Jansen&Heuning provides controlled vertical transport of bulk materials. In an optionally enclosed, dust-tight construction, the system conveys dry, fine, or granular products such as grain, sand, minerals, powders, and granulates. Plastic or steel buckets are mounted on a conveyor belt or chain.

Thanks to its modular design and a wide range of material options, Jansen&Heuning configures each installation according to the required capacity, material properties, installation height, and any applicable ATEX zone. The bucket elevators are available in steel, stainless steel, or manganese steel and can be equipped with wear-resistant linings, electronic detection, and airtight sealing.

The JHE series is used in industries such as food, chemicals, agriculture, recycling, and mineral processing. Customers integrate the elevator into unloading stations or complete processing lines. A bucket elevator is often used in combination with a chain or screw conveyor. Each configuration is developed in consultation with our engineers.

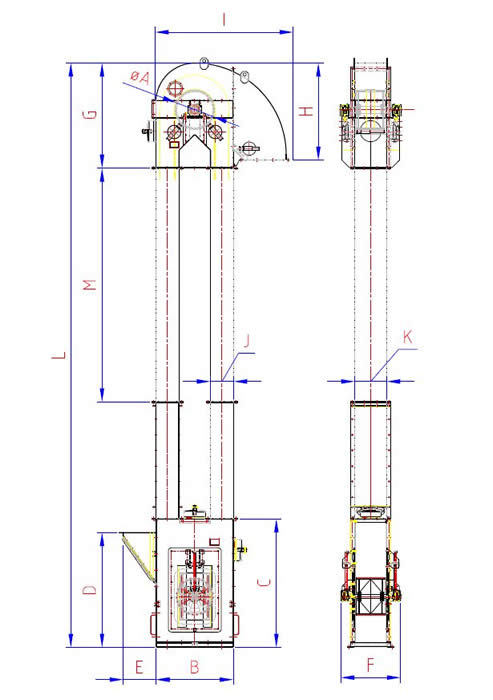

Bucket Elevator Specifications

The technical specifications of the standard bucket elevator sizes are as follows:

| Maatcode | 313 | 530 | 740 | 965 | 965Z | |

|

Drive/Return Wheel Diameter |

A | 300 | 490 | 700 | 910 | 910 |

| Foot Width | B | 620 | 1000 | 1350 | 1740 | 1740 |

| Foot Height | C | 980 | 1650 | 2300 | 3250 | 3250 |

| Inlet Height | D | 980 | 1475 | 2100 | 2850 | 2850 |

| Inlet Projection | E | 280 | 420 | 620 | 695 | 695 |

| Foot Shaft Length | F | 520 | 775 | 1016 | 1580 | 1580 |

| Head Height | G | 1030 | 1350 | 2130 | 3150 | 3150 |

| Discharge Height | H | 860 | 1250 | 1680 | 2230 | 2680 |

| Head Width | I | 860 | 1775 | 2480 | 2760 | 2760 |

| Casing Depth | J | 200 | 300 | 1360 | 1750 | 1750 |

| Casing Width | K | 200 | 410 | 590 | 950 | 950 |

| Casing Length per Section | M | 3000 | 3000 | 6000 | 6000 | 6000 |

| Number of Legs | 1 of 2 | 1 of 2 | 1 | 1 | 1 | |

| Total Length Minus Center-to-Center Distance | 1840 | 2725 | 3780 | 5080 | 5530 | |

| Capacity with High-Capacity Buckets (m³/h at 1 m/s) | 27 | 100 | 175 | 340 | 340 | |

| Capacity with Plastic Buckets for Sand and Gravel (m³/h at 1 m/s) | 16 | 80 | 130 | 226 | 320 | |

| All Dimensions in mm |

1. Drawing JHE

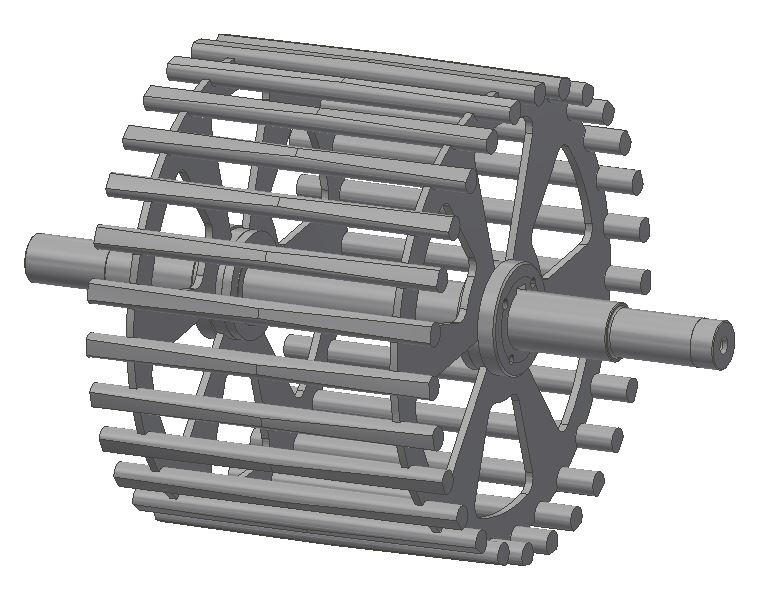

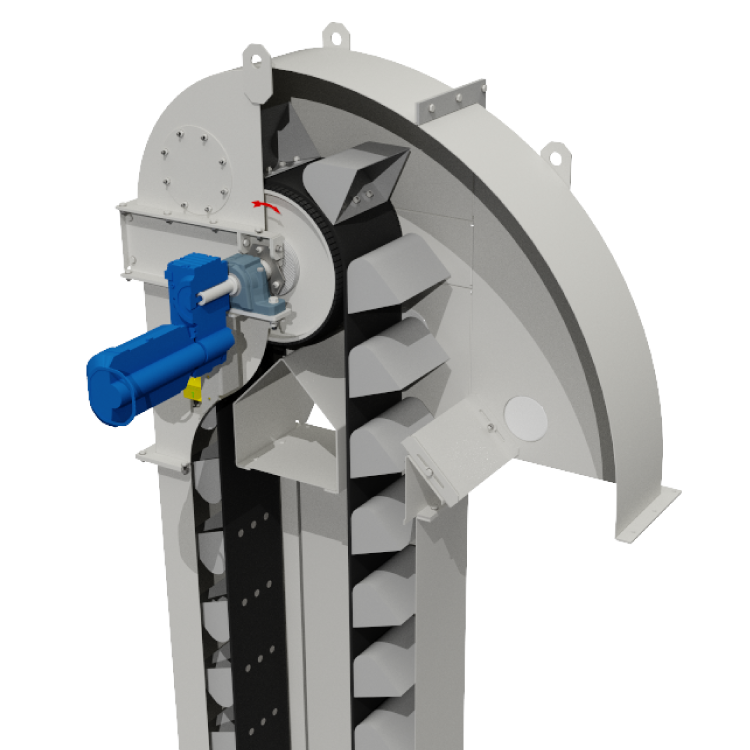

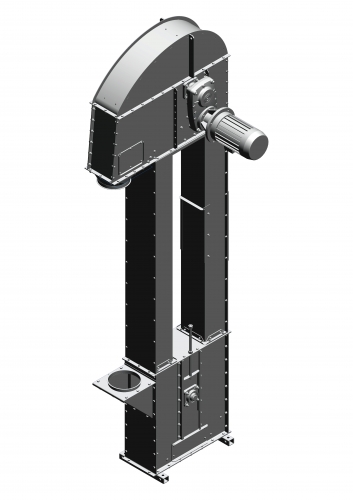

Operation Of The Bucket Elevator

A bucket elevator transports bulk materials vertically using a continuous belt or chain fitted with buckets. The material enters at the bottom, where the buckets scoop it up and carry it upward. At the top, the material discharges through centrifugal or gravity action. The enclosed construction prevents dust emission and makes the system suitable for ATEX environments.

Contact Inquiry request – bucket elevator

Benefits Of The Bucket Elevator

- Suitable for continuous vertical transport of bulk materials

- Dust-tight system, applicable in ATEX zone 21/22

- Compact footprint thanks to vertical design

- Low wear and maintenance when properly configured

- Modular construction, easy to expand

- Available in various materials: steel, stainless steel, manganese steel

- Applicable for fine, dry, and granular products

- Usable as a stand-alone unit or integrated into a complete processing line

- Maximum capacity with high-capacity buckets: up to 340 m³/h at 1 m/s

- Maximum capacity with plastic buckets for sand and gravel: up to 320 m³/h at 1 m/s

Jansen&Heuning Calculation Tool

The JH calculation tool determines the appropriate bucket elevator based on your input parameters. Technical drawings of standard configurations are available on request. Because a bucket elevator must integrate seamlessly into your installation, Jansen&Heuning specialises in delivering fully customised solutions.

Contact

For more information or a tailored quotation, please contact Jansen&Heuning:

- Phone: +31(0)50 3126 448

- E-mail: sales@jh.nl

- Contactform: www.jh.nl/contact

Watch the video

The video shows the entire process at Jansen&Heuning, from fabrication and transport to installation of bucket elevator type JHE313 at Maltha Glass Recycling.