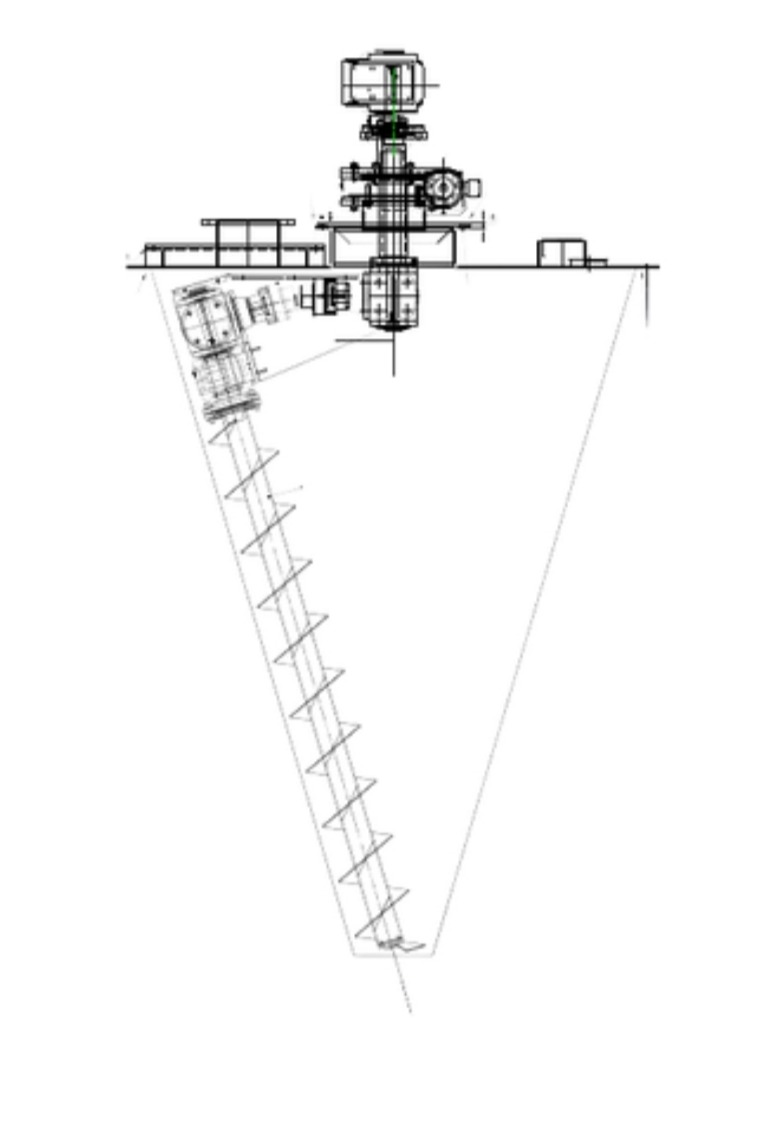

Description Cone mixer

The cone mixer is a batch mixer for the careful mixing of powders, granulates and moist bulk materials. Thanks to its conical shape and central screw with orbital movement, products are mixed evenly without damaging their structure. The mixer is suitable for applications that require high mixing accuracy and minimal product residue. The cone mixer can be integrated into existing processing lines and complies with strict hygienic standards.

Mixer suitable for

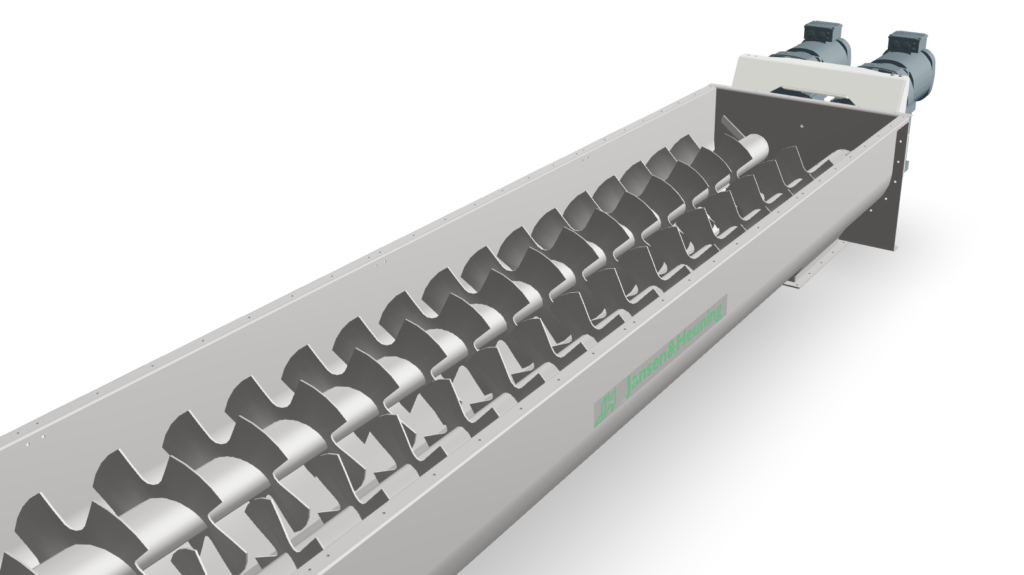

The cone mixer is suitable for mixing fragile, fine or poorly flowing products. Due to its low rotational speed and three-dimensional mixing action, this mixer is highly suitable for use in the food industry, chemicals, minerals processing and recycling.

Benefits of the cone mixer

The cone mixer delivers a homogeneous mixing result, even at low fill levels. Thanks to the orbital screw motion, the product is mixed gently and evenly without causing damage or segregation. The conical shape enables almost complete discharge, which speeds up cleaning and minimizes residue. Its low speed keeps energy consumption low and limits wear on components. The compact design allows for easy integration into existing installations. Maintenance and inspection can be performed quickly thanks to good accessibility.

Technical design tailored to your process

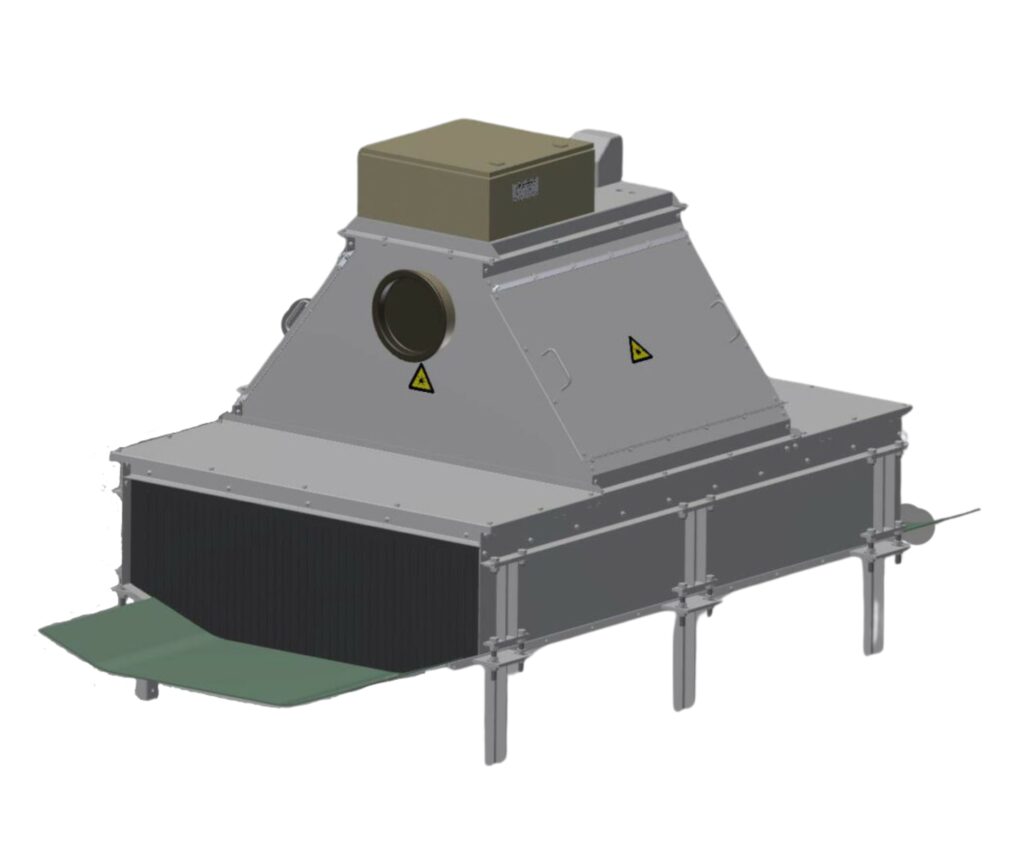

The conical mixer is fully tailored to the process and the environment in which it is used. Every part is custom-built, from the drive system to the frame and from material selection to connection points.

The mixer consists of a conical vessel with a central mixing screw. Its orbital drive with planetary motion ensures a uniform mixing result, even for products with varying flow properties. The large discharge opening enables fast emptying with minimal product residue.

The design can be made in stainless steel or coated steel, depending on requirements for hygiene, corrosion or abrasion resistance. Inlet ports for liquids or additives can be integrated. Cleaning systems such as CIP or WIP are optional, as well as inspection hatches and access openings.

For specific needs, the vessel can be heated or cooled. ATEX-compliant versions, level sensors, weighing systems and custom supports are available. Everything is designed in consultation and matched to your installation.

Options for

- ATEX version

- Heated or cooled vessel

- Cleaning systems (CIP/WIP)

- Weighing system and level sensors

- Customer-specific connections and support frames

Contact

For more information or a tailored quotation, please contact Jansen&Heuning:

- Phone: +31(0)50 3126 448

- Email: sales@jh.nl

- Contact form: www.jh.nl/en/contact