Description Continuous mixer

Jansen&Heuning’s continuous mixer is designed for efficient and continuous mixing of diverse product flows. Its purpose is to ensure constant, homogeneous and high-quality product quality. This industrial mixer processes both dry substances and finely divided bulk materials. The capacity goes up to a maximum of 120 m³ per hour. Because mixing takes place inline, the production process is optimised. This creates an even composition of components over the entire flow, with continuous output. Thanks to customised dimensions and variable control, the mixing intensity can be precisely tuned to the material to be processed. Think of powders, granulates or other bulk materials. For this reason, the continuous mixer offers a flexible solution for a variety of industrial processes where uniform mixing quality is required.

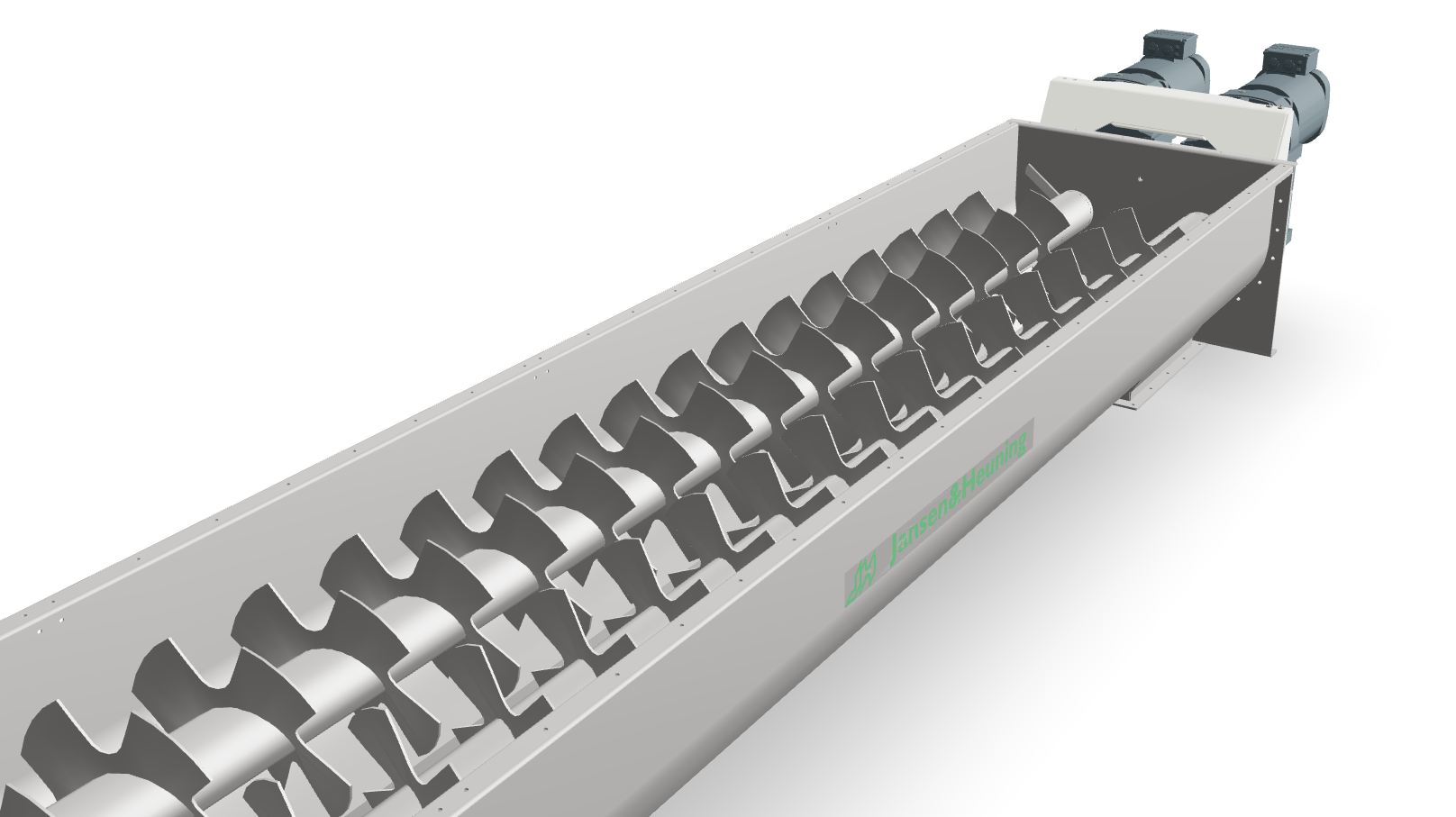

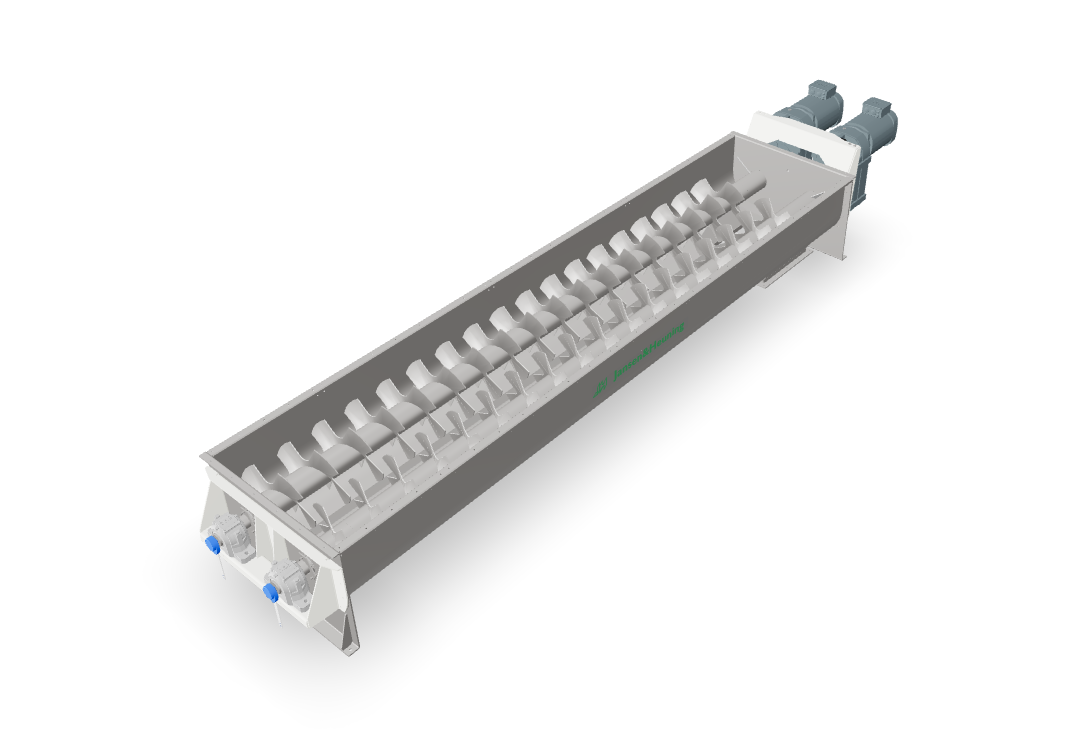

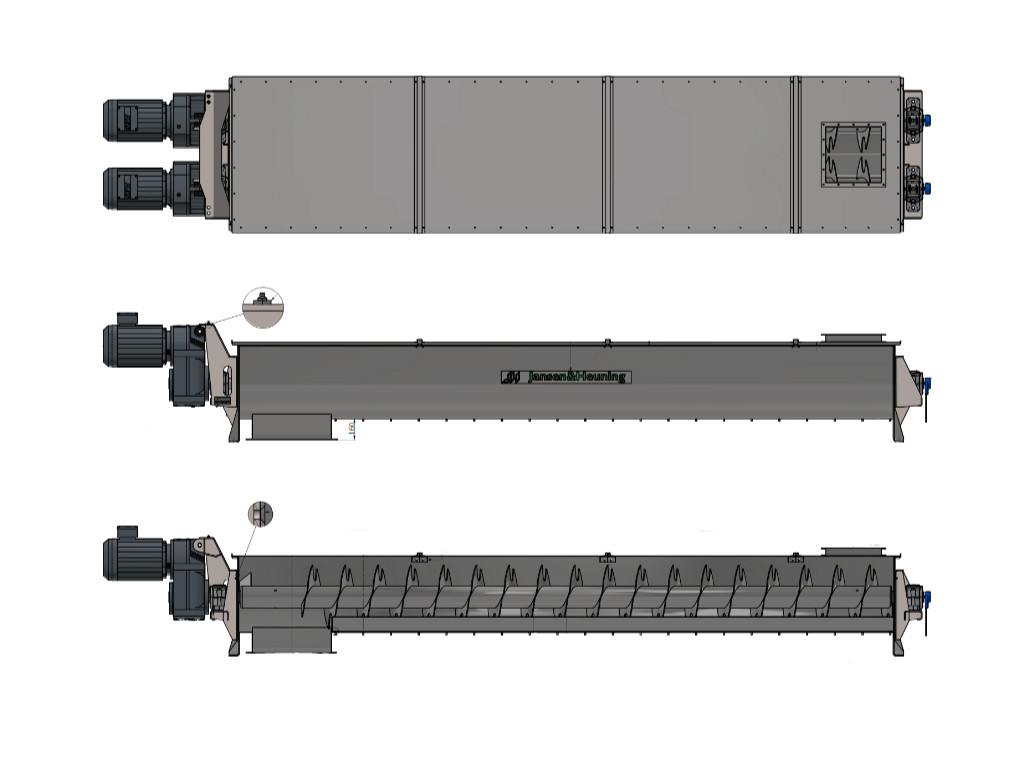

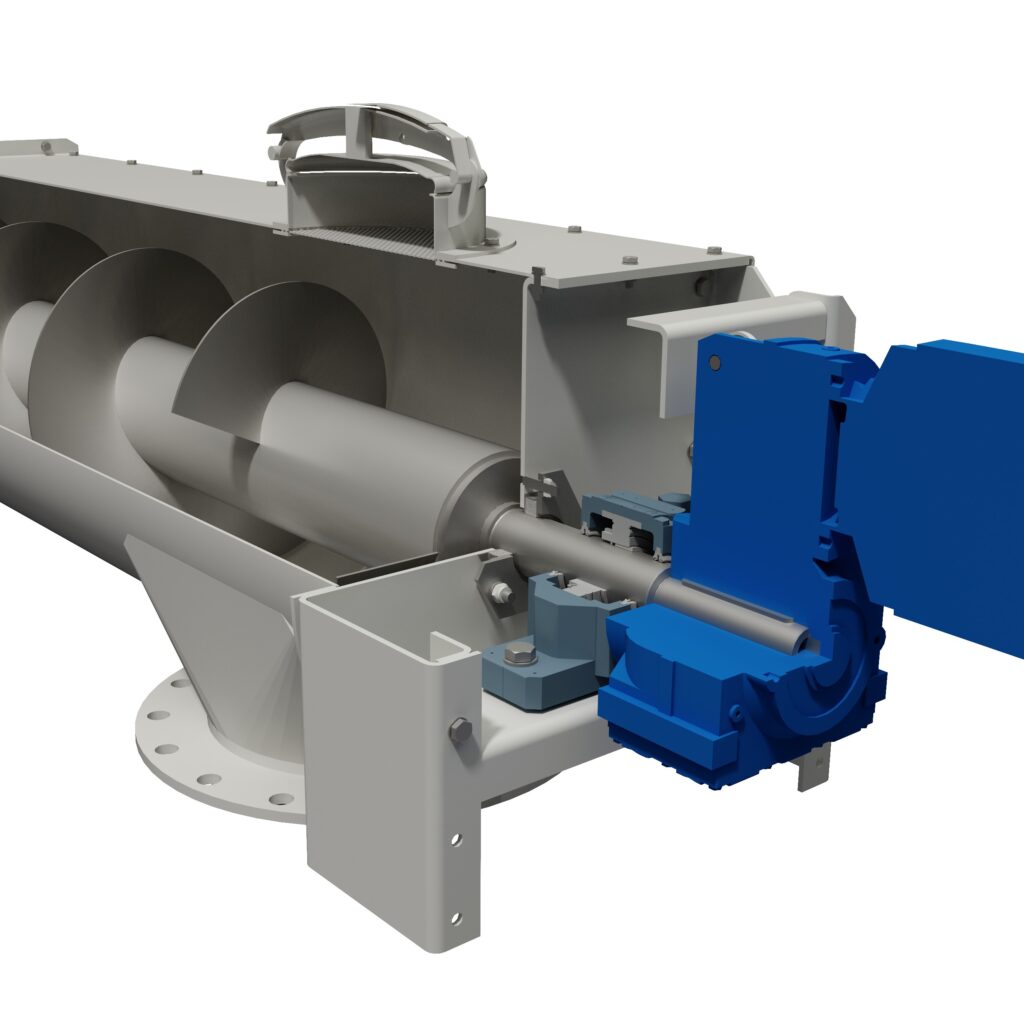

The machine consists of two separately driven mixing gases. These are fitted with paddles or special screw blades mounted on solid shafts. The horizontal mixer is constructed so that the mixing gases can be easily replaced. Critical components such as drives, bearings, shaft ends or seals do not have to be dismantled in the process. This design minimises downtime and reduces maintenance costs.

Operation of continuous mixer

During the mixing process, the two parallel mixing gases ensure a constant and controlled product movement. Thanks to the adjustable mixing speed, the mixing time can be adapted to the material properties. Examples of this are particle size, moisture content and flow behaviour. The result is an optimised mixture that meets the process and capacity requirements.

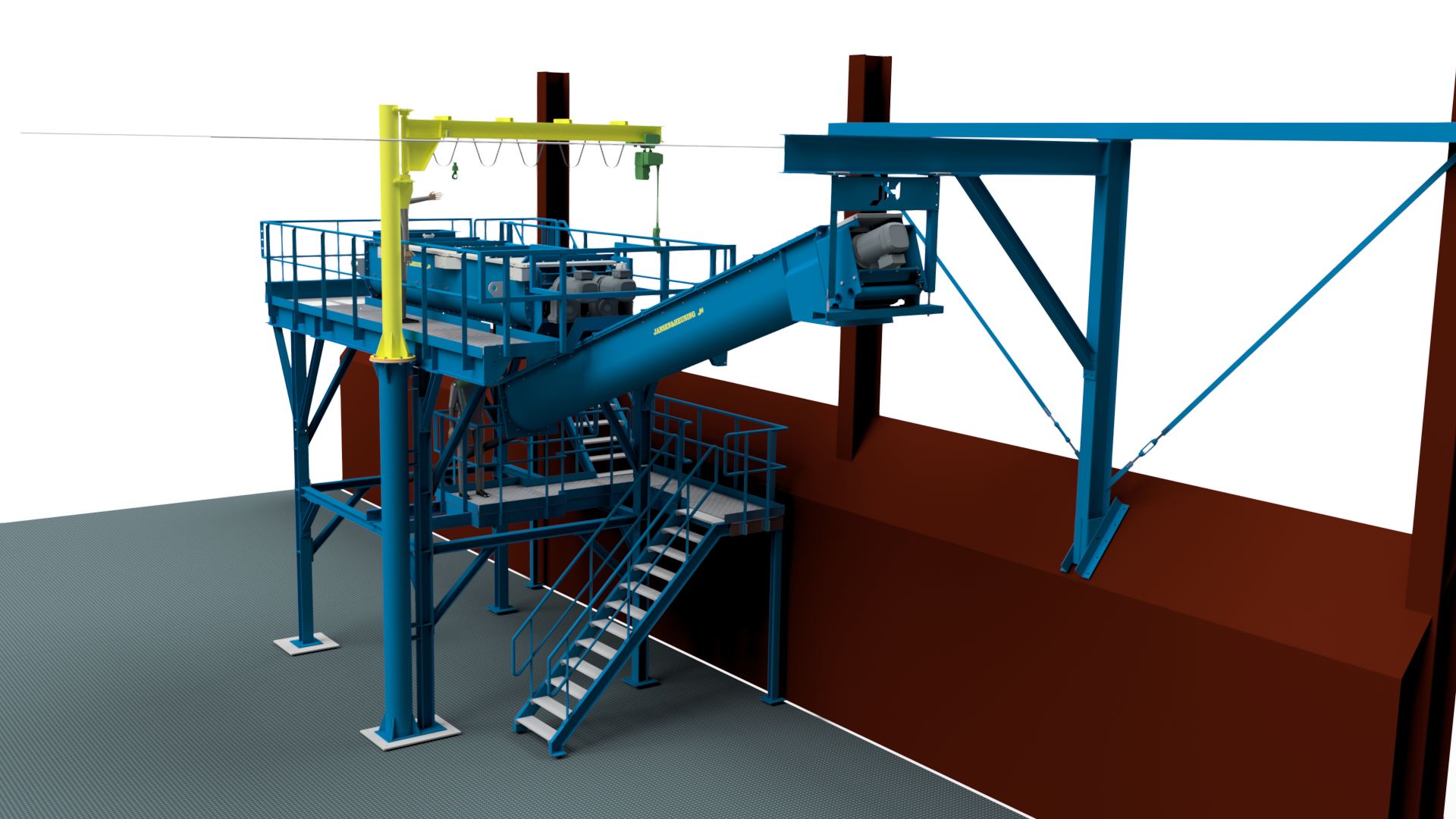

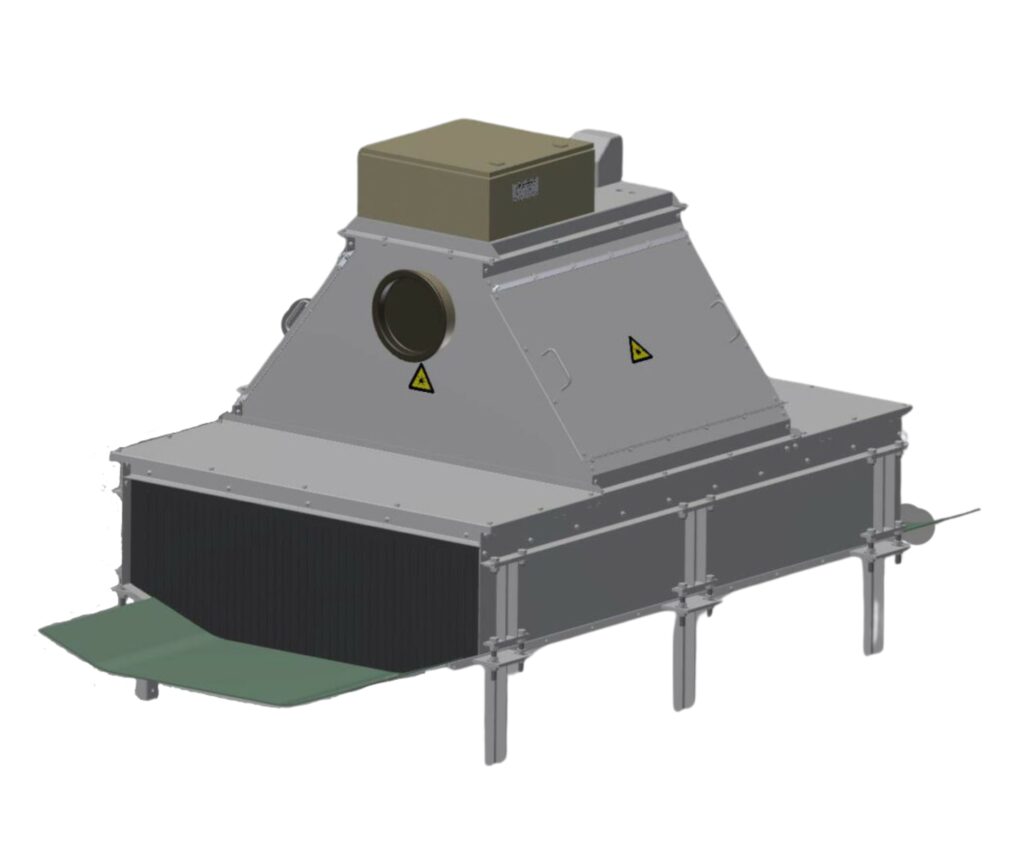

The product flows continuously through the horizontal mixer. Specially developed paddles ensure uniform and efficient mixing. Thanks to the continuous flow and homogeneous distribution, the product quality remains constant even with fluctuating feed capacities. Screw conveyors can be used for efficient material feed to the continuous mixer. These ensure a constant and controlled feed. In addition, machines for conveying bulk materials, such as dosing or hopper systems, can further optimise and automate the process. This inline mixing system is particularly suitable for processes where a constant mixing quality is required. The system can be easily integrated into automated process lines. Applications include the mixing of powders, granulates and bulk solids in the food industry, animal feed production, chemicals and minerals processing.

Finally, the robust design combined with flexible mixing settings offers a long-lasting solution. This makes the continuous mixer from Jansen&Heuning ideal for demanding industrial processes where homogeneity and process efficiency are crucial.

Technical design tailored to your process

The continuous mixer is always built according to the installation it will be part of. Dimensions, motor power and material specifications are defined based on the application and the product to be processed.

Wear plates are optional and available in materials such as HARDOX 400 or plastics like HMPE. The housing itself can also be made from various steel types, depending on the operating conditions.

If needed, one or more nozzles can be integrated for the addition of liquids or steam during mixing. Everything is engineered to match your process and requirements.

Contact

For more information or a tailored quotation, please contact Jansen&Heuning:

- Phone: +31(0)50 3126 448

- Email: sales@jh.nl

- Contact form: www.jh.nl/en/contact