Moving bulk materials may seem straightforward at first glance, but in practice it involves many variables. Each product behaves differently: grain flows easily, while sand or minerals put much more weight on the installation. Environmental factors such as dust generation or limited installation space also play a role. This makes selecting the right conveyor essential. The right match prevents downtime, saves energy, and extends the lifetime of the installation. At Jansen&Heuning we see every day how the right solution makes the difference, whether it is an efficient belt conveyor in a transshipment terminal or a dust-tight screw conveyor in a feed mill.

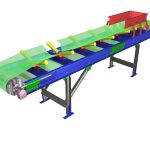

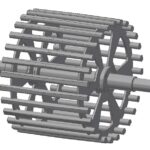

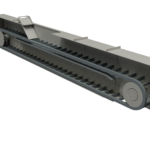

Belt Conveyor

A belt conveyor is the efficient solution for longer conveying distances and high capacities. This system handles a wide range of bulk materials, such as grain, fertilizer, sand and gravel. Thanks to the continuous belt movement, the load on the product remains low, keeping damage to a minimum.

Companies choose a belt conveyor when large volumes need to be moved reliably and with low energy consumption. The system can be used in terminals, transshipment stations and production environments, but also in situations where dust-free conveying or a stable product flow is required. Compared to screw or chain conveyors, a belt conveyor is often more economical for long distances because the drive power required remains relatively low.

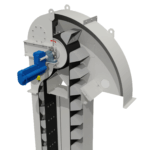

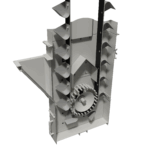

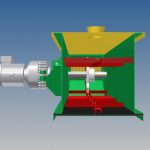

Bucket elevator

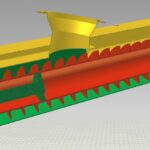

For vertical transport of bulk materials, the bucket elevator is the standard solution. This system is used for a wide variety of products, such as grain, fertilizer and minerals, as well as other bulk goods with different bulk densities. Depending on the required capacity and the type of material, different executions with belts, chains and buckets can be selected.

A bucket elevator is frequently applied in grain silos, feed mills and industrial production lines where continuous conveying over large heights is required. Thanks to its enclosed housing, the system operates with low dust emissions and helps maintain product quality. Compared to other vertical conveying systems, the bucket elevator combines high capacity with relatively low energy consumption, making it suitable for both bulk storage and process installations.

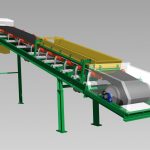

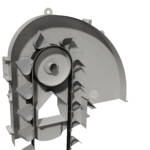

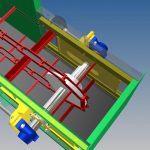

Chain Conveyor

When heavy, hot or abrasive materials need to be conveyed, the chain conveyor provides a reliable solution. Its robust design makes the system resistant to high loads and intensive wear. This makes it particularly suitable for horizontal and slightly inclined conveying of bulk materials that are too heavy or rough for a belt or screw conveyor.

Chain conveyors are widely used in the recycling industry, steel processing and in heavy-duty installations where operational reliability is essential. Thanks to their enclosed construction, they can operate with low dust emissions, keeping the working environment cleaner. In addition, the system can be built in a modular way, allowing a chain conveyor to be easily integrated into existing production lines or transshipment facilities.

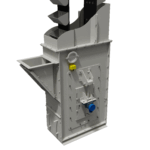

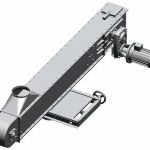

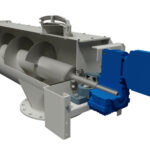

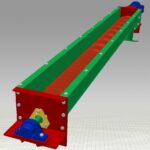

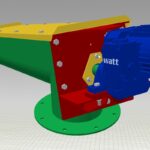

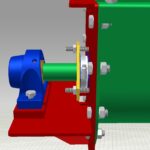

Screw Conveyor

A screw conveyor is suitable for short to medium conveying distances and is widely used for transporting dry bulk materials such as flour, cement, minerals and granulate. Depending on the design, it can be supplied as a U trough with covers or as a fully enclosed tubular screw. This makes the screw conveyor well suited for production environments where dust-free conveying is required.

The system can operate both horizontally and at a slight incline, and it can be easily integrated into existing installations. Screw conveyors are often applied in silo discharge, mixing installations and dosing processes where a constant product flow is essential.

Special Conveyors and Custom Solutions

Not every application fits within standard solutions. For specific circumstances, Jansen&Heuning develops custom-made systems, such as mobile conveyors or combinations of belt, chain and bucket elevator designs. These solutions are engineered in close cooperation with the customer and tailored to the available space, required capacity and product characteristics.

Conclusion

The choice of the right conveyor depends on several factors: conveying distance, capacity, bulk density, product characteristics and environmental conditions. By carefully weighing these parameters, it is possible to design a solution that will operate reliably for many years.