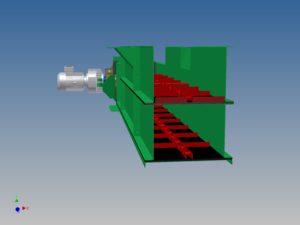

By applying a complete plastic wear plate on the bottom of the chain conveyer, a long life of the bottom is obtained.

The chain is supported over the entire surface and not only slides over the links of the chain, but also the carriers carry with it.

It appears that the energy consumption is about 20% lower than with other systems. The friction of the product over the plastic is lower than over steel.

As an example of the service life:

At Tate & Lyle we have supplied chain conveyors for their soaking tubs for corn. We had to replace the plastic bottom of the main distribution chain after 15 years. There they turn around 1,300 tons of corn per day, 340 days per year, which amounts to almost 5 million tons in total, and only then the first simple maintenance of plastic parts is required. Corn contains a lot of sand and abrasive material.