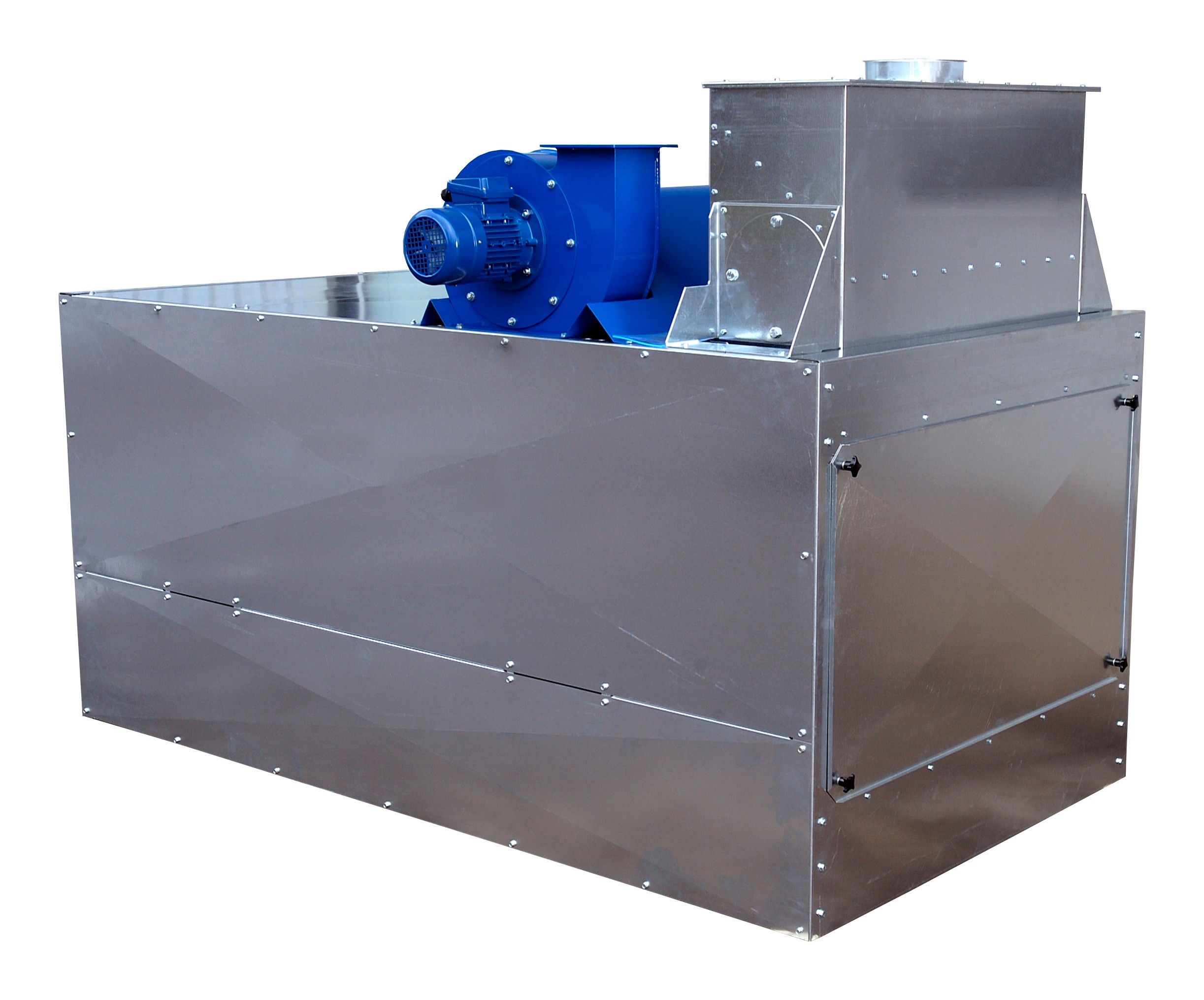

Description Grain cleaner

Function

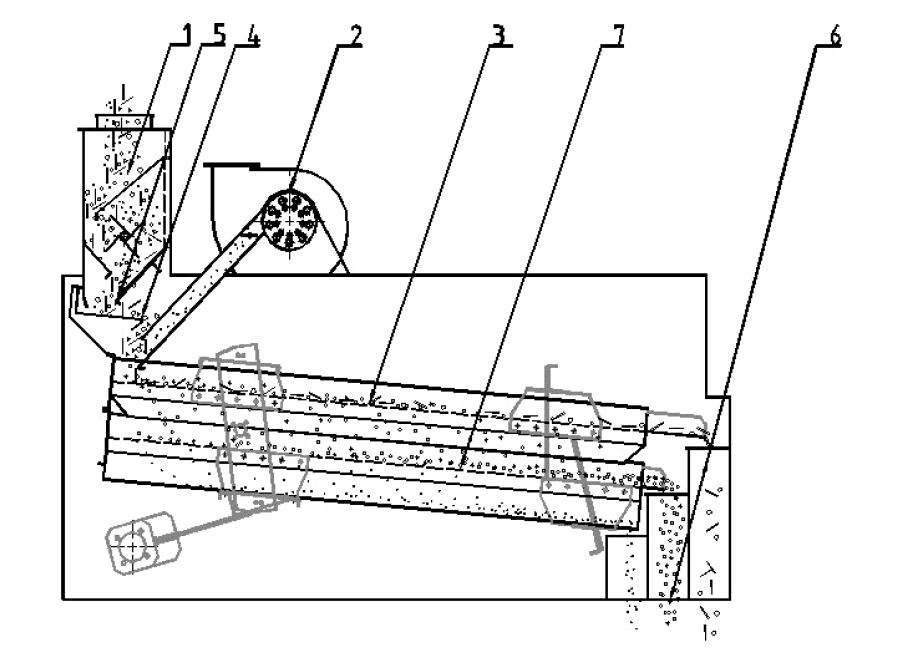

The raw material is transported into the inlet bin (1), then it enters the de-awner (5) (optional). There must always be material in this bin to ensure an even distribution over the presuction area (4). The fan (2) is located on the machine. After the presuction the material ends up on the top screen layer (3) for pre-cleaning. The bottom screen layer (7) is for fine-cleaning. The clean product will then leave the machine (6).

What makes these machines unique?

- the cleaners from Jansen&Heuning are available in 2 types the UniSeed (JHUS30) and the DuoSeed (JHDS60)

- the grain is equally distributed over the parallel working screen sections. The machines are made of steel with wooden sieve boxes and expansion chambers

- the sieves can be replaced from the inlet side

- sieve cleaning with rubber balls

- combined pre- and after suction for optimal adjustment

| Type |

JHUS30

|

JHDS60

|

| capacity (tons/hour) fine-cleaning |

8

|

16

|

| capacity (tons/hour) pre-cleaning |

30

|

60

|

| weight (kg) |

930

|

1860

|

| length (mm) |

2465

|

2480

|

| width (mm) |

1290

|

1290

|

| height of inlet (mm) |

1675

|

2850

|

| total sieve area (m²) |

4

|

8

|

| number of sieves |

4

|

8

|

| installed power (kW) |

4,05

|

5,05

|

| capacity fine-cleaning based on barley with 14% moisture capacity pre-cleaning based on barley with 18% moisture |

||