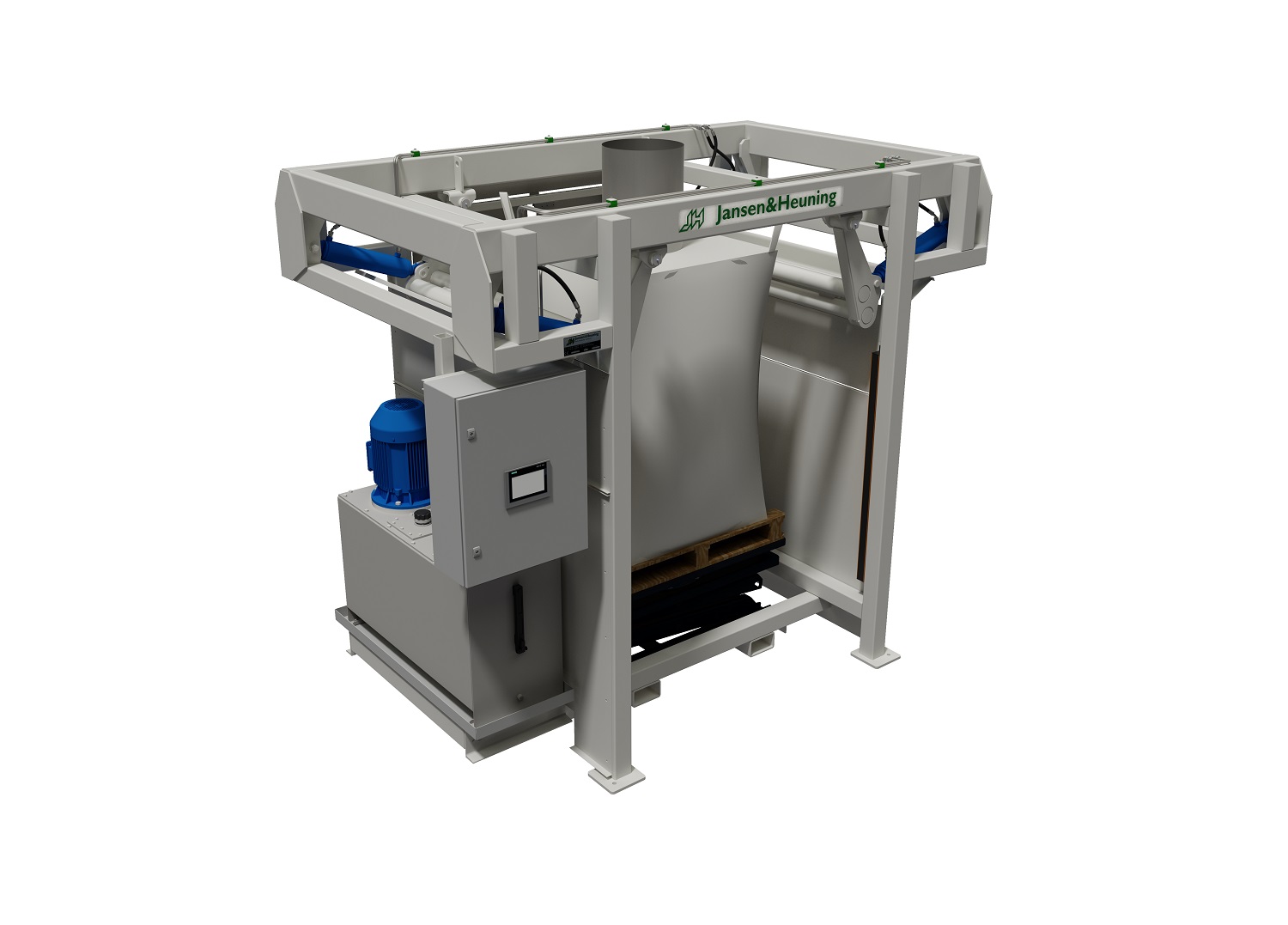

Description Big bag crusher fully automatic

Are the contents of your bigbags getting hard and are you looking for a machine that automatically crushes your bigbags at the push of a button? Then the bigbag crusher fully automatic from Jansen&Heuning is the right choice. This bigbag conditioner features a turntable and lift table to crush the bigbags from all sides and at any desired height. In the included control box with touchscreen control panel, you can easily add and change (up to 300) crushing programmes, making a customised programme available for different bigbags. For example, you can set the height between crushing steps, the force of the crushing movement and the rotation of the turntable per programme.

Fully automatic bigbag crusher operation

The operator places a bigbag on the lift table with turntable using a forklift truck; once the forklift truck has moved away, the operator can select the right programme on the crusher. Crushing is then started at the push of a button. The big bag is then crushed in eight steps, after which the turntable rotates 90°. The eight crush steps are then repeated again on the other side of the bigbag. As soon as the big bag is fully crushed, the operator can remove it from the station with the forklift truck, after which the big bag can be processed further.

Specifications FIBC crusher fully automatic

- Two hydraulically controlled articulated arms, one scissor table with turntable

- In eight steps, the crusher presses a bigbag from different sides and at different heights. The contents thus break up into small chunks

- Steel control cabinet with 7-inch HMI touchscreen

- PLC Siemens Type S7, 1214 C

- A 32 amp electrical supply is required up to the control side

- Hydraulic power pack

- Scissor table loadable to 2000 kg

- Turntable 90°, rotating left and right

- Light curtain to protect the operator

- The automatic crusher is fully assembled and tested in our factory

Options

- Railings to protect the working area of the machine

- Raised version for processing big bags with a height of up to 2.2 m